2022-03-11

Thread is widely used in the industrial field, mainly for connection, transmission and sealing. Thread is often used in the assembly of parts, thread quality directly affects the assembly accuracy and safety performance of parts.

Therefore, it is very important to detect whether the thread accuracy meets the standard. Today, WE will talk about common thread detection methods.

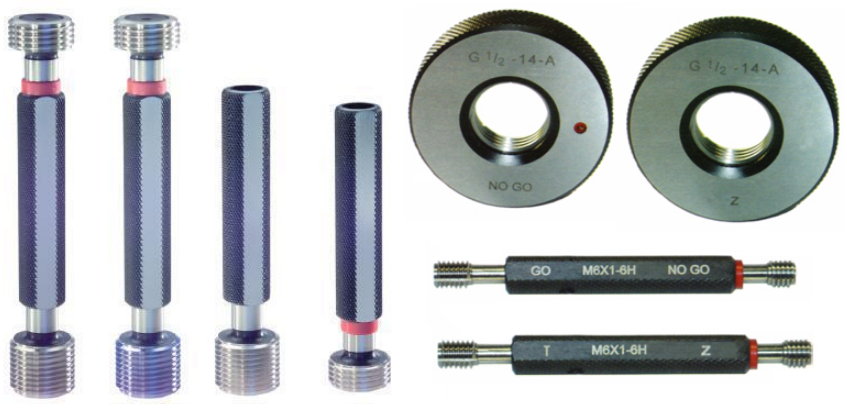

1.Thread GO/NO GO Gauge detection method

According to the Taylor principle, the traditional GO/NO GO test method can only meet the minimum requirements of thread testing. The advantages of this method are fast, economical and practical.

However, the shortcomings of this inspection method are also obvious: it only qualitatively detects whether the thread is qualified or not, cannot provide the numerical value of the single parameter of the thread, and cannot provide the reason for the failure. The parameters such as pitch, half Angle and shape error cannot be individually controlled quantitatively. False fit may occur in the twisting, resulting in untraceable measurement results, and this often causing controversy.

2. Micrometer measurement

The thread micrometer is a special thread measuring tool. The thread micrometer has a special measuring head. The shape of the measuring head is made to match the thread shape. Each pair of measuring heads can only be used to measure threads with a certain pitch range.

Because the thread probe of the thread micrometer has a certain angle error, and the pitch and flank angle of the external thread of the workpiece also have a certain error. This method is mainly used for the measurement of the pitch diameter of the external thread of the common workpiece with low precision requirements.

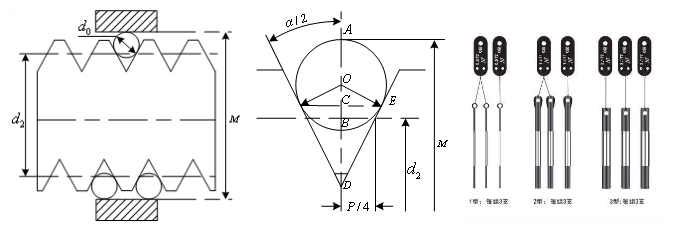

3. Thread three-stitches method

Three-stitches are a set of three measuring needles with the same diameter determined to measure the pitch diameter of the thread by indirect method. By placing three threaded measuring needles into the tooth sockets on both sides, using a micrometer, length measuring machine, etc. to read the M value. And calculating the thread single pitch diameter by the functional relationship between the pitch diameter of the thread and the diameter of the measuring needle/the profile angle and the pitch.

The measurement results of this method need to be corrected by a number of errors. If not corrected, a large error will be introduced and the measurement results will be different.

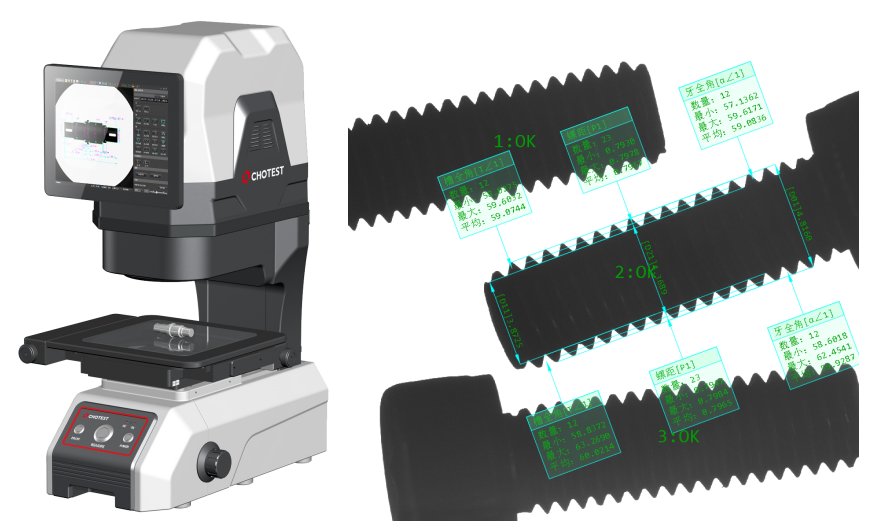

4. Image measurement method

The commonly used instruments for the image measurement method of threaded workpieces are Image measuring machine, Video measuring machine etc., which use image recognition to measure the parameters of threaded workpieces.

VX series flash measuring machine can realize batch measurement of external threads with one key, and easily obtain parameters such as large, medium and small diameters, tooth angle, and pitch of threads. It has high measuring efficiency and is very suitable for mass production inspection.

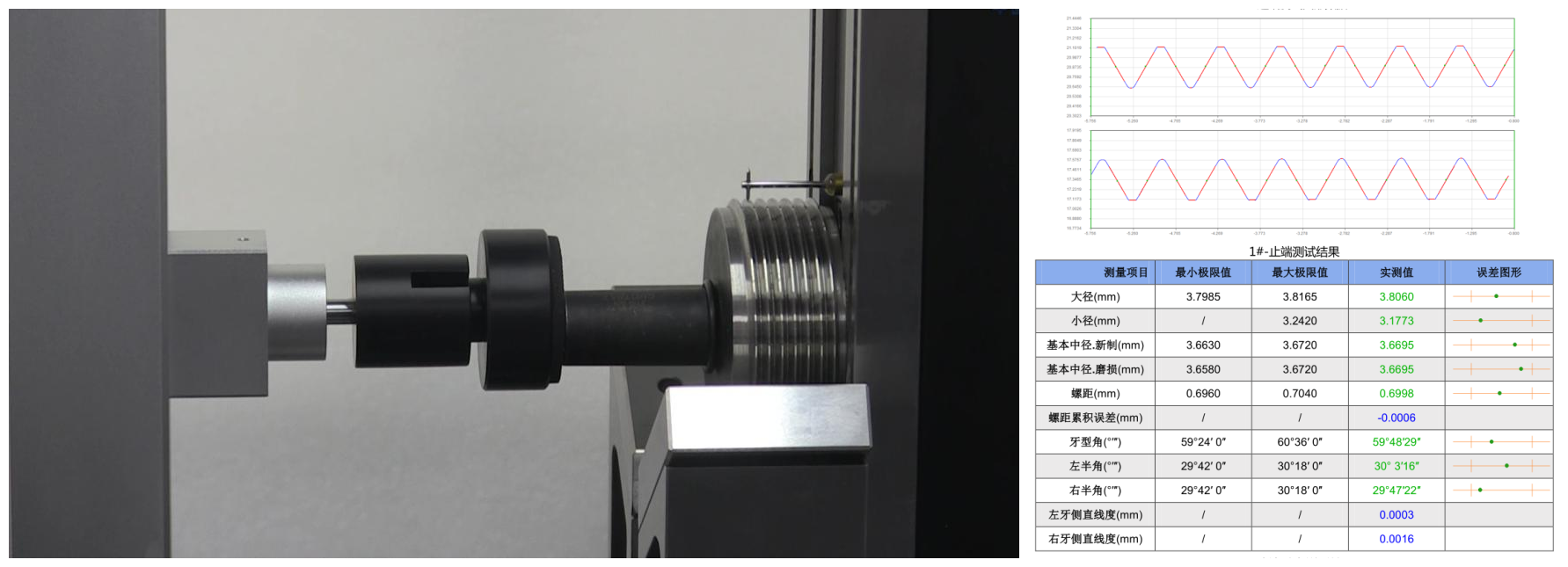

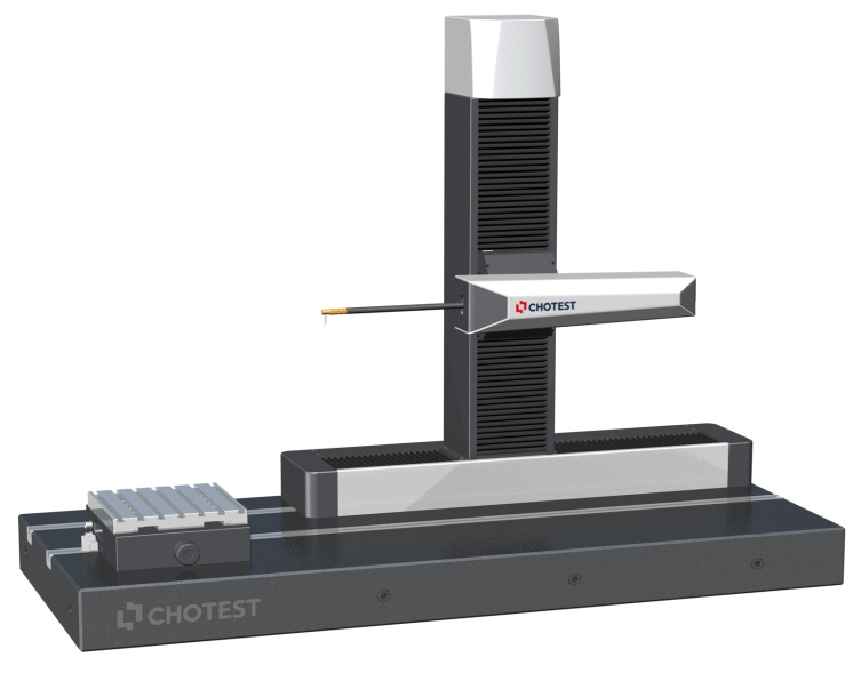

5. Stylus scanning measurement method

SJ5780 high-precision intelligent profile roughness measuring machine continuously scans and measures the upper and lower profile surfaces of the thread axial section, and then calculates the pitch, tooth half angle, taper of the thread and other parameters according to the obtained profile information.

SJ5780 high-precision intelligent profile roughness measuring machine can measure the size of internal and external threads. It can not only measure common cylindrical threads and conical threads, but also measure large-slope threads such as trapezoidal threads, buttress threads, and sawtooth threads, and multi-thread threads. It can also easily measure the long oil pipe thread and long stroke screw. The standard database of SJ5780 covers varieties of standards from countries standards to international standards. With the comprehensive and powerful functions, it could considered as a good tool for thread measurement.