SuperView W3 Optical 3D Surface profilometer is an ideal instrument for sub-Nanometer measurement of various precision parts. Based on the principle of white light interference technology, combined with precision Z-direction scanning module and 3D modeling algorithm, it contactlessly scans the surface of the object then establish a 3D image for the surface. A serial of 2D, 3D parameters reflecting surface quality of the object are obtained after XtremeVision software processes and analyzes the 3D image. The SuperView W3 is a user-friendly precision optical instrument with powerful analysis functions for all kinds of surface form & roughness parameters. With unique light source it could measure various precision parts with both smooth and rough surface.

| Model No. | SuperView W3 | ||

| Size | 1000*900*1550mm | ||

| Weight | 500 kg | ||

| Light source | White LED | ||

| Video system | 1024×1024 | ||

| Objective Lens | 10x(2.5x,5x,20x,50x,100x optional) | ||

| Optical Zoom | 0.5x(0.75x,1x,0.375x optional) | ||

| Standard F.O.V. | 0.98×0.98 mm | ||

| Lens Turret | Motorized 5 holes-turret | ||

| XY Object table | Size | 450×450mm | |

| Travel Range | 300×300mm | ||

| Loading Capacity | 10kg | ||

| Control Method | Motorized | ||

| Tilt | ±5° Motorized | ||

| Z Axis | Travel Range | 100mm | |

| Control Method | Motorized | ||

| Z-Stoke Scanning Range | 10mm | ||

| Z Resolution | 0.1nm | ||

| Roughness RMS Repeatability *1 | 0.005nm | ||

| Stage Height Measurement | Accruacy *2 | 0.3% | |

| Repeatability *2 | 0.08% 1σ | ||

|

Enviromental Requirement |

|||

| 1 | Operating environment: No strong magnetic field | 4 | Environmental vibration: VC-C or better |

| 2 | Working temperature: 0 °C~30°C fluctuation <2℃/60min | 5 | Compressed air: 0.6Mpa oil-free, water-free |

| 3 | Relative humidity: 5%~95% RH, no condensation | 6 | Power: 300W |

Remark:

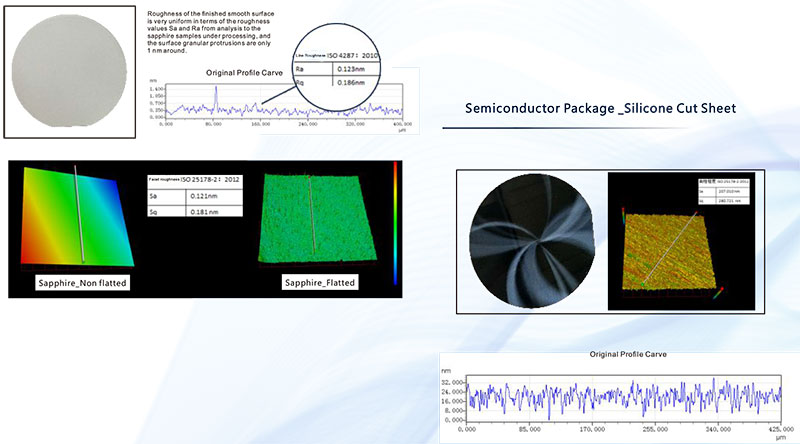

*1 Measure Sa 0.2nm silicon wafer in a laboratory environment according to the ISO 25178

*2 Measure standard 5 μm steps height block in a laboratory environment according to the ISO 10610-1:2009

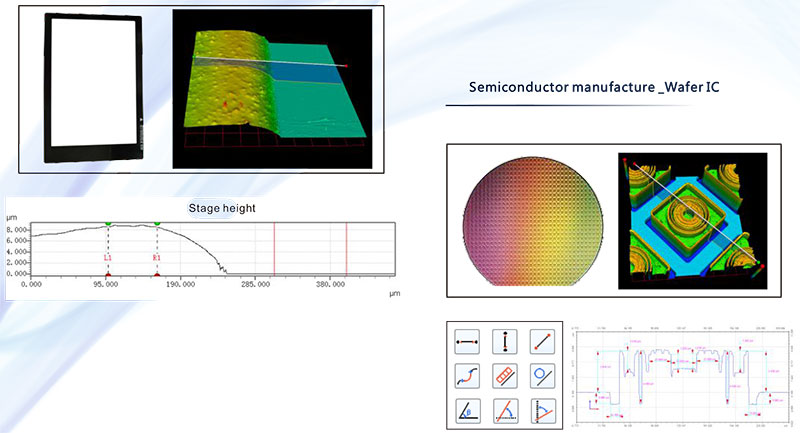

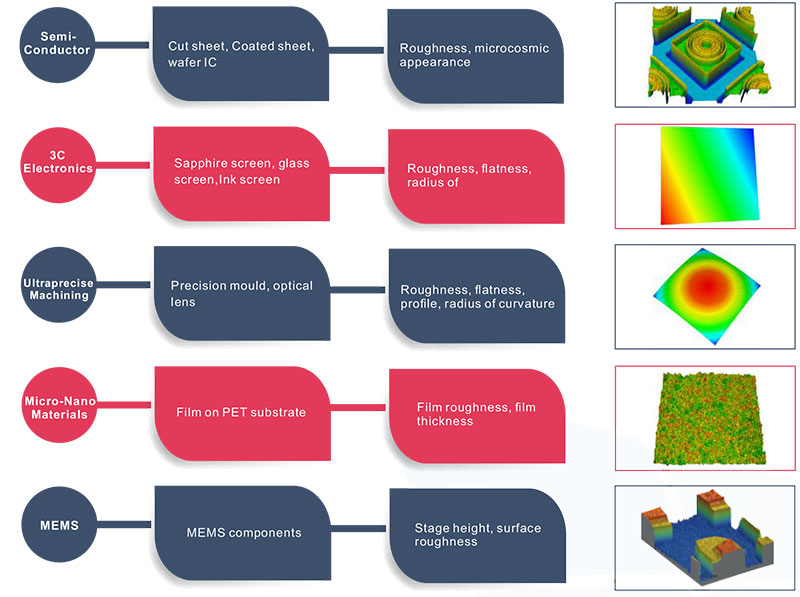

It is used for measurement and analysis of surface roughness and profile of precision components from industries of semi-conductor, 3C Electronics, ultraprecise machining, optical machining, micro-nano materials, micro-electro-mechanical system.

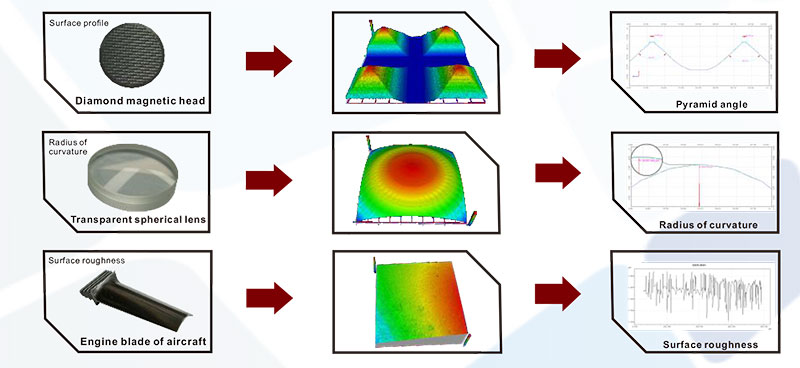

Measurement and analysis for various products, components and materials`surface form and profile characteristics, such as flatness, roughness, waviness, appearance, surface defect, abrasion,corrosion, gap, hole, stage, curvature, deformation, etc.

3C Electronics_Sapphire crystal

3C Electronics _ Ink screen