2024-05-24

Tube and plate heat exchanger is a kind of energy-saving equipment to realize the heat transfer between materials, which plays an important role in the production process of petrochemical industry. Whether it is to improve production efficiency, ensure product quality or energy saving, all play an indispensable role.

Measurement requirements

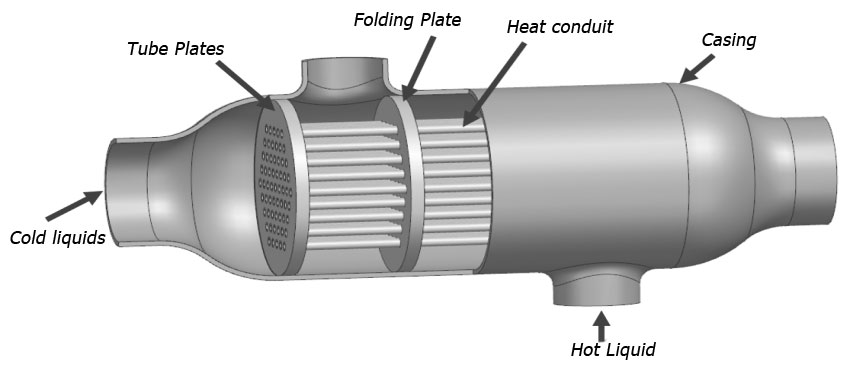

Tube and plate heat exchanger has a number of tube plate and folding plate, each tube plate and folding plate have a number of tube holes, the heat conduction tube bundle parallel through the folding plate and tube plate, tube bundle ends are fixed on the tube plate by welding, in order to make each tube bundle can be installed in the tube plate and folding plate smoothly, in the actual production need to make sure that each heat conduction tube corresponding to the tube holes must be in the same axis, and each tube plate and folding plate need to be kept in parallel during installation and fixing process.

Schematic diagram of heat exchanger

Traditional Measurement Programs

In the past, for the heat exchanger heat conduction tube bundle installation is mainly used for manual wire measurement method, the use of manual wire measurement method is not only time-consuming and labor-intensive, and the accuracy can not meet the requirements of modern industry.

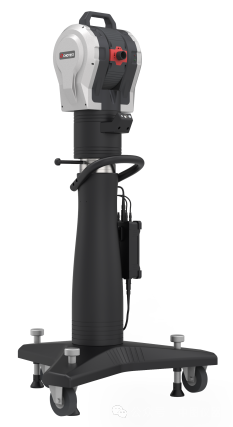

In recent years, laser trackers have been widely used in the field of tube and plate heat exchanger measurement due to their high accuracy and efficiency. The laser tracker utilizes the collimation of the laser beam and ranging technology to quickly and accurately measure key dimensions of the heat exchanger, such as the position of the tube holes and the flatness of the tube plate, etc. The laser tracker can also be used for the measurement of the tube plate heat exchanger.

1. High precision: the measurement precision of laser tracker can reach micron level, which meets the strict requirements of petrochemical industry for heat exchanger size control;

2. High efficiency: compared with the traditional measurement method, laser tracker can be easily operated by a single person, which greatly shortens the measurement time and improves the working efficiency;

3. Large measuring range: the maximum measuring radius of the laser tracker can be up to 80 meters, which can meet the needs of a variety of specifications for size measurement;

4. visualization of data: laser tracker automatically records and stores measurement data, visualization graphics clearly show the data of each part, quickly guide the assembly;

5. Flexible measurement: the laser tracker can move freely in space, adapting to different measurement environments and objects.

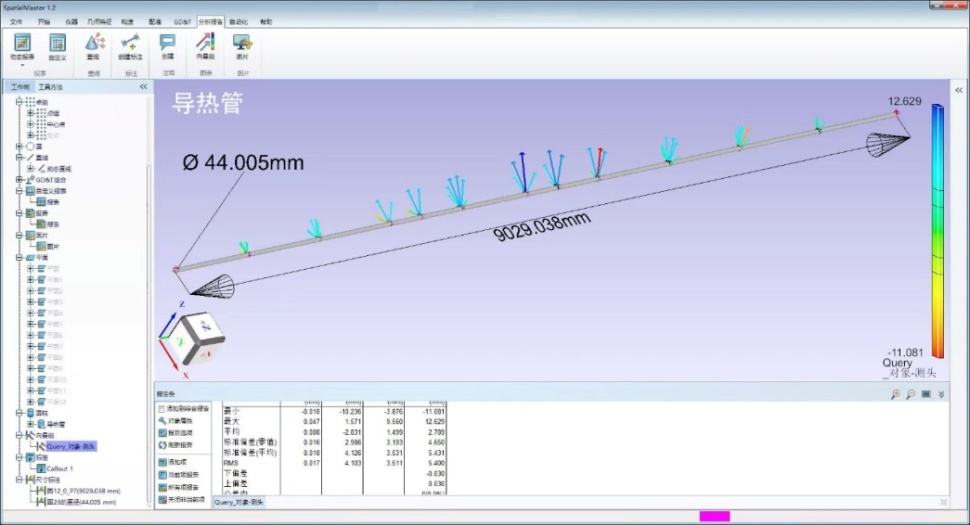

1. Heat pipe installation measurement

The following figure shows the measurement data of the heat pipe, through the vector group query function in the SpatialMaster analysis software, it is easy to see that the heat pipe is deformed in the middle part of the installation process, and it can be adjusted according to the deformed position and direction of the heat pipe in the software view to improve the assembly accuracy.

Heat conduit data analysis chart

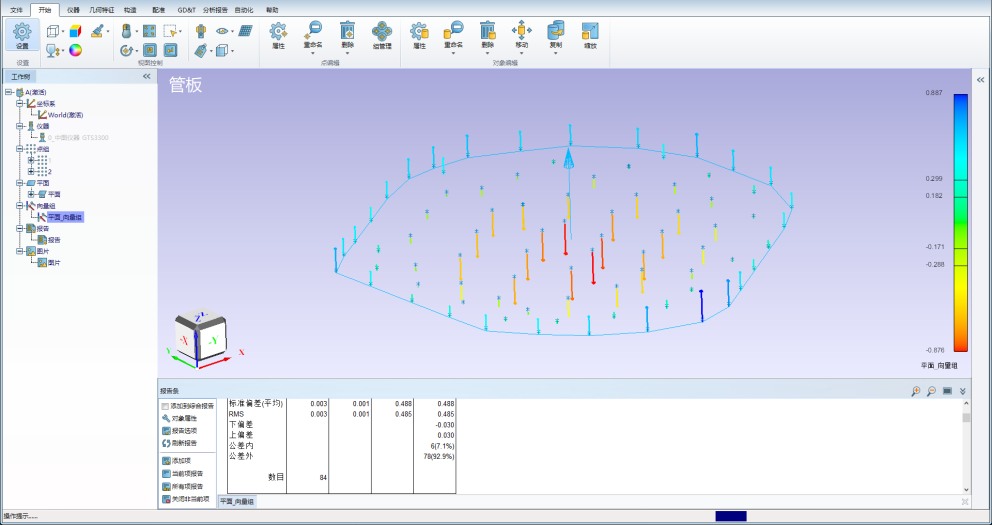

2. Measurement of the flatness of the tube plate and folding plate

In order to ensure the parallelism of the tube bundles during installation, it is necessary to ensure that the flatness of the individual tube plates and folding plates meets the requirements in the actual production, and the flatness of the tube plates and folding plates can be measured by using the GTS3600 model laser tracking instrument with a 1.5-inch high-precision SMR reflective target sphere.

Tube Sheet Data Analysis Chart

GTS series laser tracker has the features of high precision, large measuring range, simple installation and easy operation, etc. In the above case, GTS series laser tracker not only meets the measurement needs of the product, but also improves the installation precision of the product, and provides digital guarantee for the installation of large-size parts.