2024-06-06

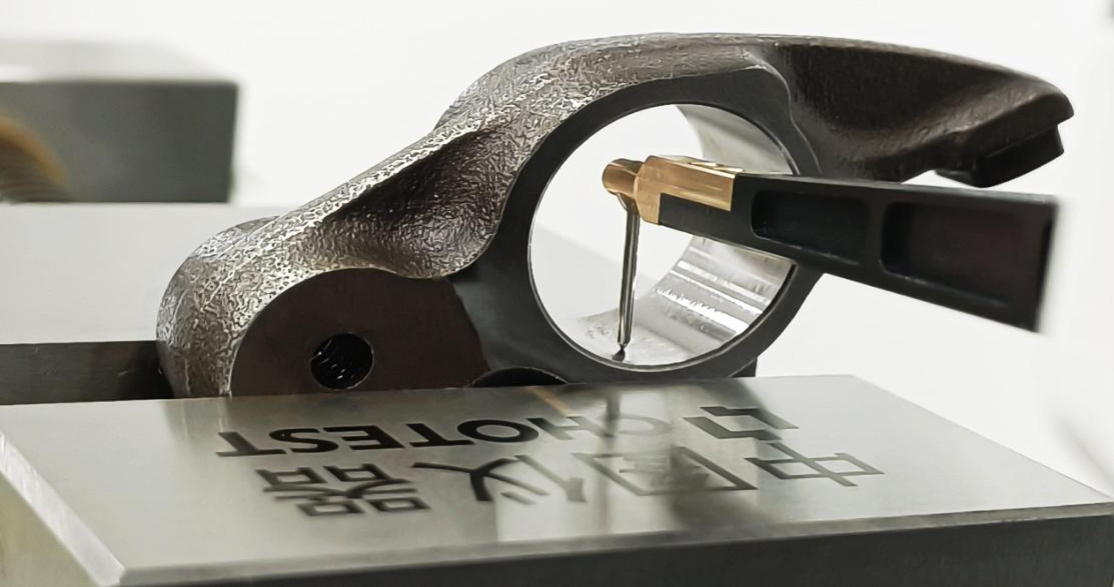

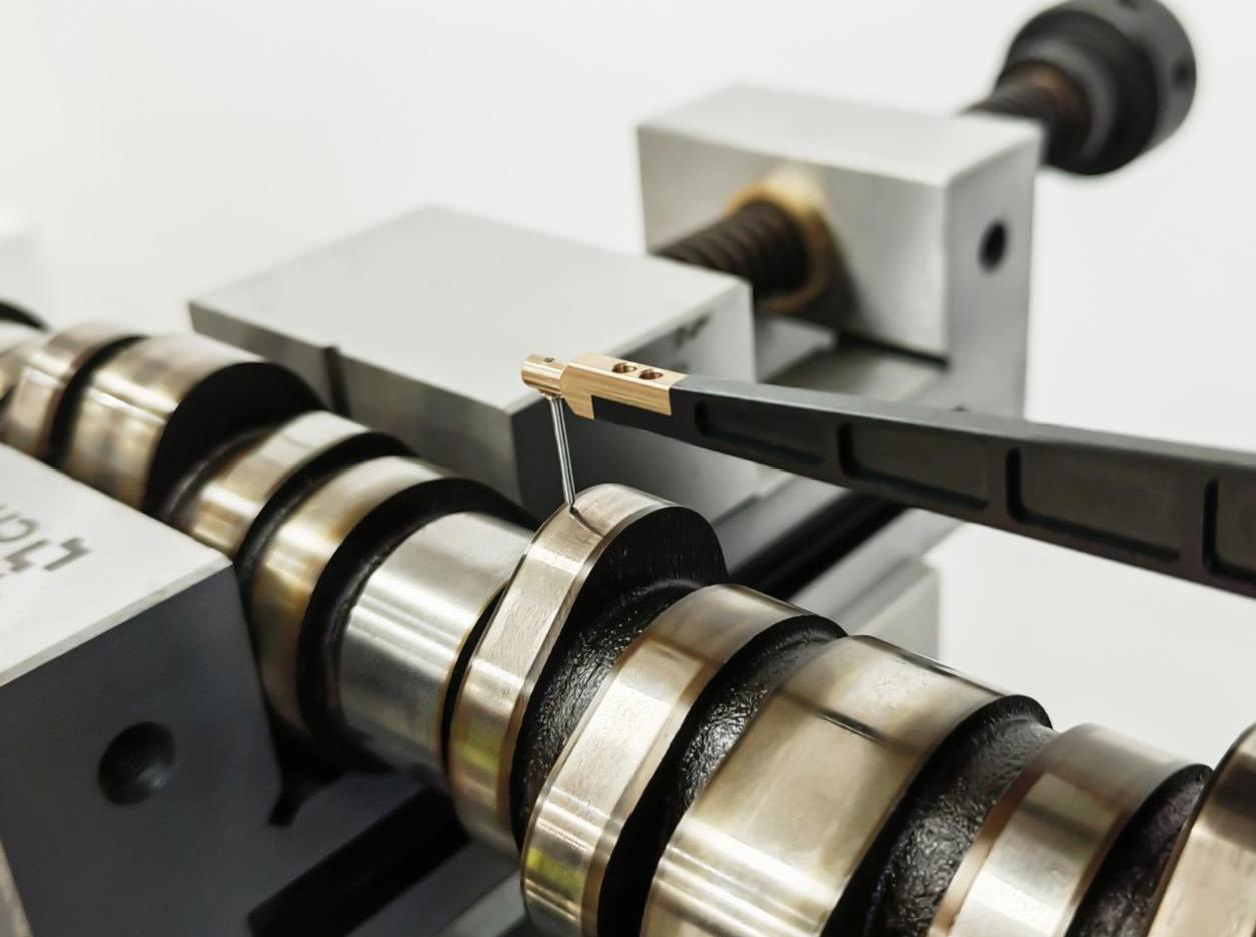

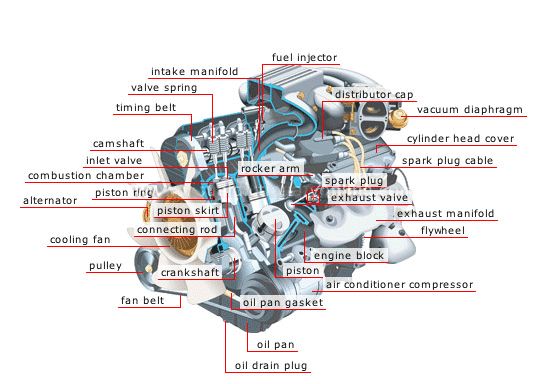

The engine is the heart of an automobile, providing power to the vehicle. With the development of the automotive industry, the demand for inspecting engine components has increased significantly. This is especially true for critical components such as camshafts, crankshafts, connecting rods, drive rocker arms, spark plugs, piston rings, and others. The macro and micro surface profiles of these key components directly impact engine performance and determine its lifespan.

The macro and micro surface profile parameters for critical automobile engine components are extremely stringent, and conventional measurement instruments are inadequate for conducting these inspections. Some foreign companies have developed specialized measurement instruments for crankshafts and other critical engine components, but their high prices have significantly hindered the rapid development of China’s domestic engine industry.

【Internal Structure Diagram of an Automobile Engine.】

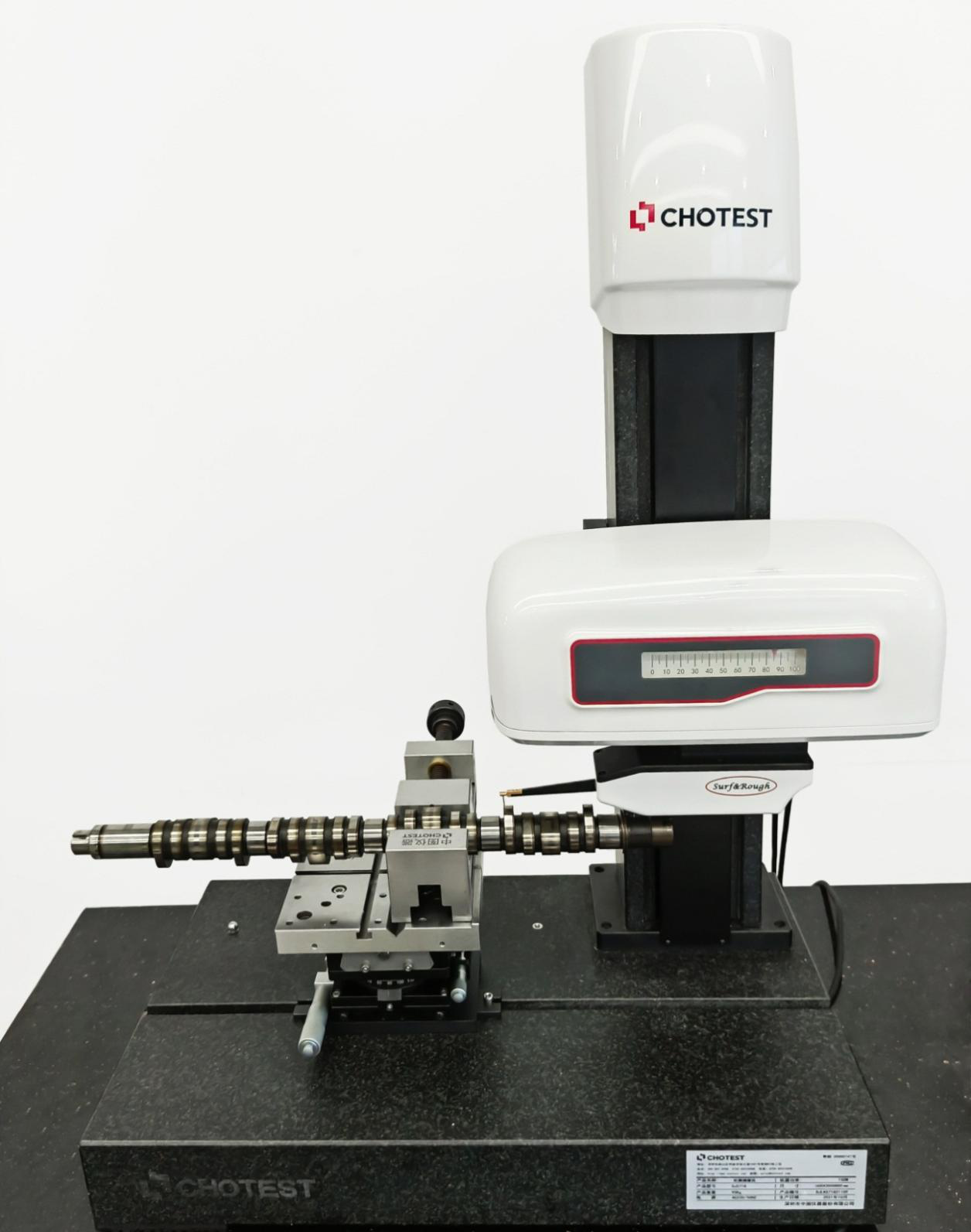

The CHOTEST SJ5800 high-precision roughness and contour integrated measuring instrument, developed independently in China, boasts powerful product features and high-precision measurement capabilities that can meet the profile dimension measurement requirements for critical engine components.

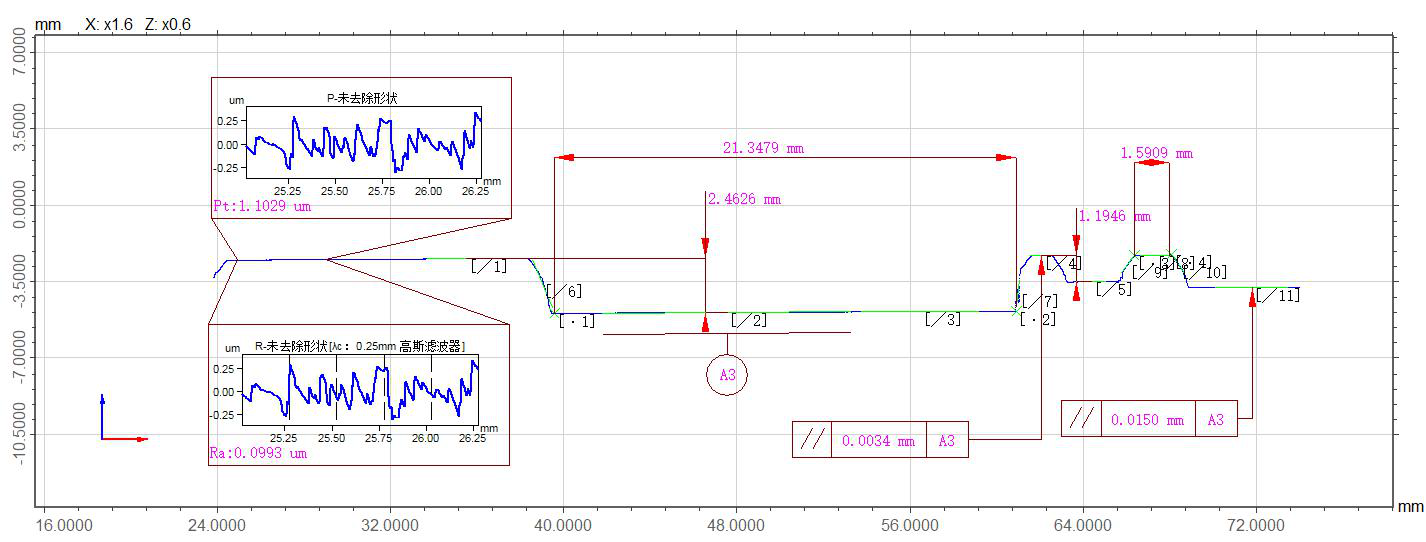

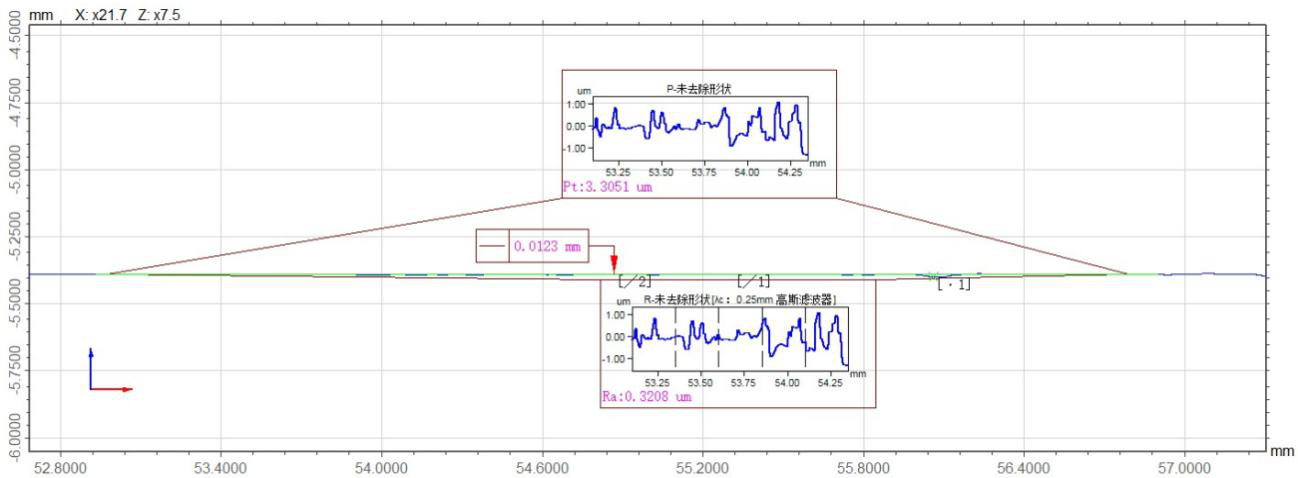

SJ5780 can perform one-time scanning measurements of surface contour, waviness, and roughness on parts. It is especially suitable for large curved surfaces and inclined planes, allowing simultaneous roughness and contour dimension checks. For features like circular arcs, spheres, and irregular surfaces, it provides measurements of various roughness parameters (such as Ra, Rz) and micro-profile depth (Pt) as well as waviness parameters.