2024-05-21

As China’s manufacturing industry continues to move towards precision and high-end technology, higher demands are placed on inspection methods and capabilities. The 3D contour measuring instrument, with its Z-axis measurement accuracy reaching the micron level, plays a significant role in advanced manufacturing due to its ultra-high measurement precision.

The CHOTEST VJ series 3D contour measuring instrument is a non-contact scanning 3D contour imaging device used in fields such as semiconductors, 3C electronics, medical devices, magnetic materials, and precision machinery. The workpiece does not require positioning; it is automatically recognized, and a quick flash measurement is taken to easily obtain 2D/3D parameters. It features a line laser probe that can suppress the influence of multiple reflections and diffuse reflections on the sample surface, achieving ultra-high precision measurements.

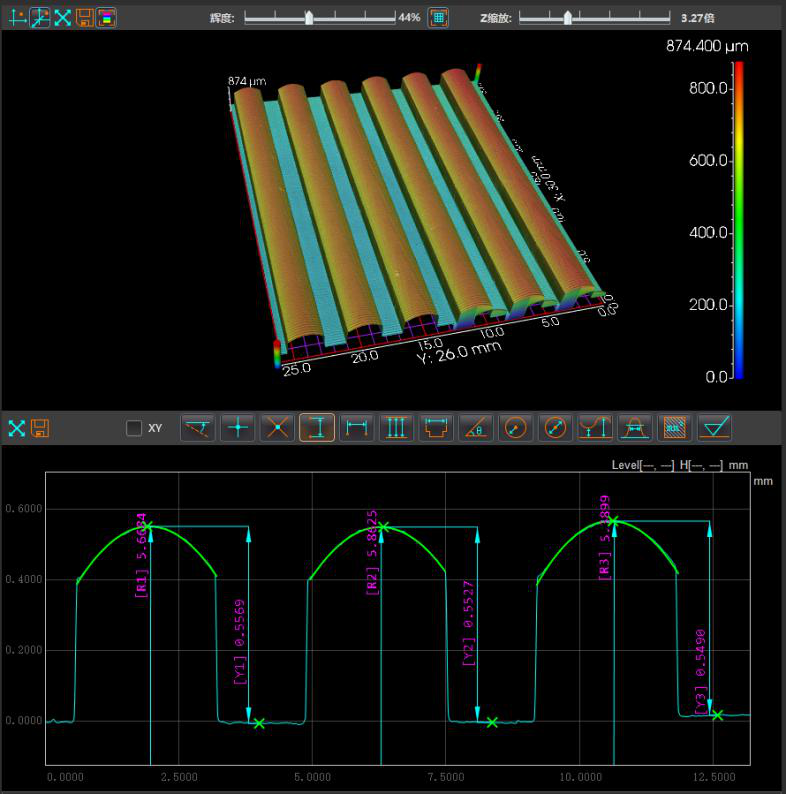

The image above displays the three-dimensional morphology of the workpiece. The VJ series 3D contour measuring instrument can present the true shape of the target workpiece with ultra-high precision within seconds. The 3D image with varying colors is created by the software using height measurement data to display the elevation differences. The software can select the corresponding measurement surface to quickly obtain information about the highest and lowest points.

electronic circuit measurement

The VJ series 3D contour measuring instrument scans the surface of electronic circuit samples, revealing the groove contours clearly, as shown in the image above. By extracting a cross-sectional profile curve from the image, the groove’s contour curve can be clearly seen. At this point, the contour analysis function is used to annotate the height and other dimensional data of the feature area. A rich set of 2D measurement tools allows for various measurements of height, width, angle, and R angles through the cross-sectional shape.

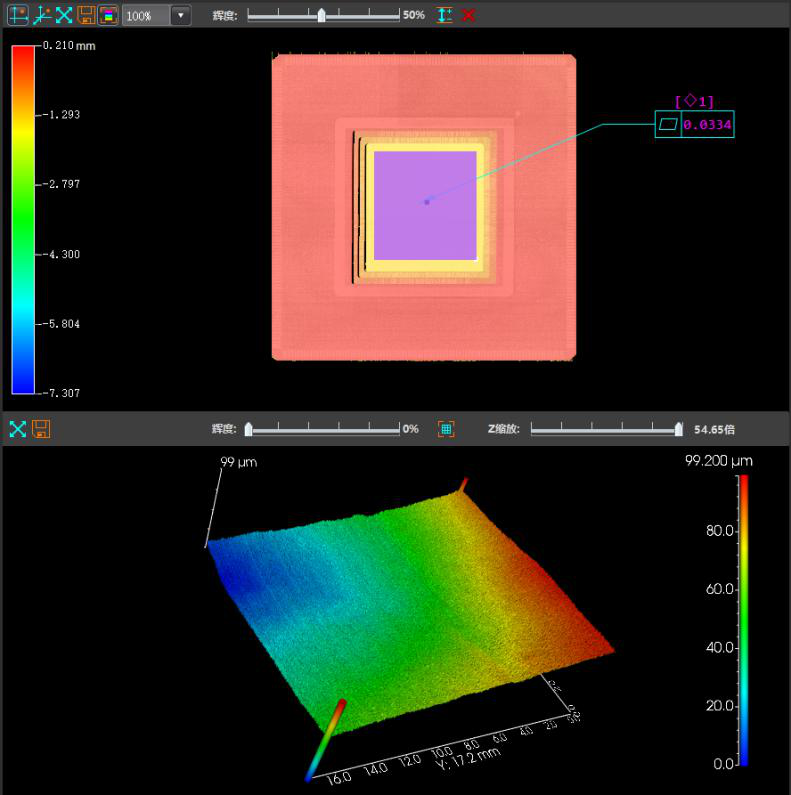

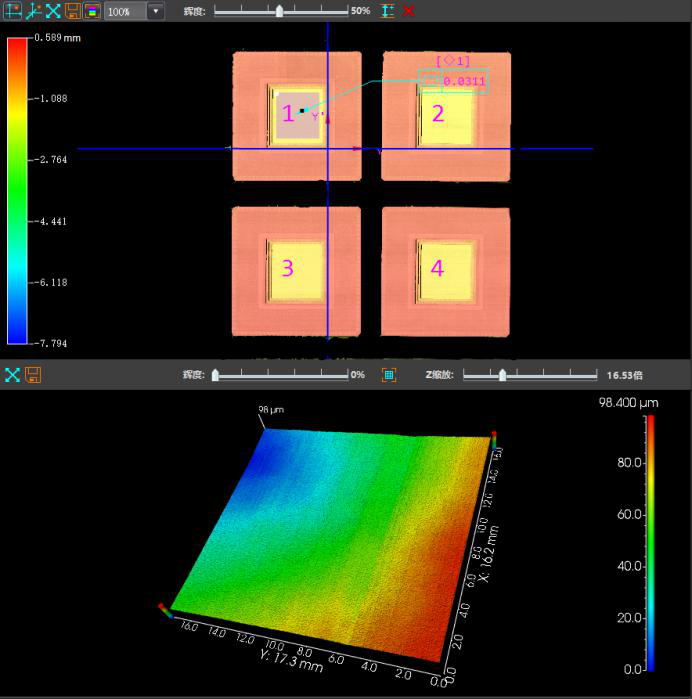

Semiconductor measurement

In addition to 2D size measurement, the VJ series 3D contour measuring instrument can also freely perform 3D geometric calculations on workpieces (such as the semiconductor workpiece shown in the image above), including form and position tolerances like flatness, coplanarity, and roundness.

For batch measurement of multiple workpieces, the software can establish templates. In CNC mode, simply pressing the start button allows the instrument to automatically locate the measurement object based on the shape of the workpiece, match the template, evaluate the measurement, and generate reports, truly achieving one-click rapid and accurate measurement.

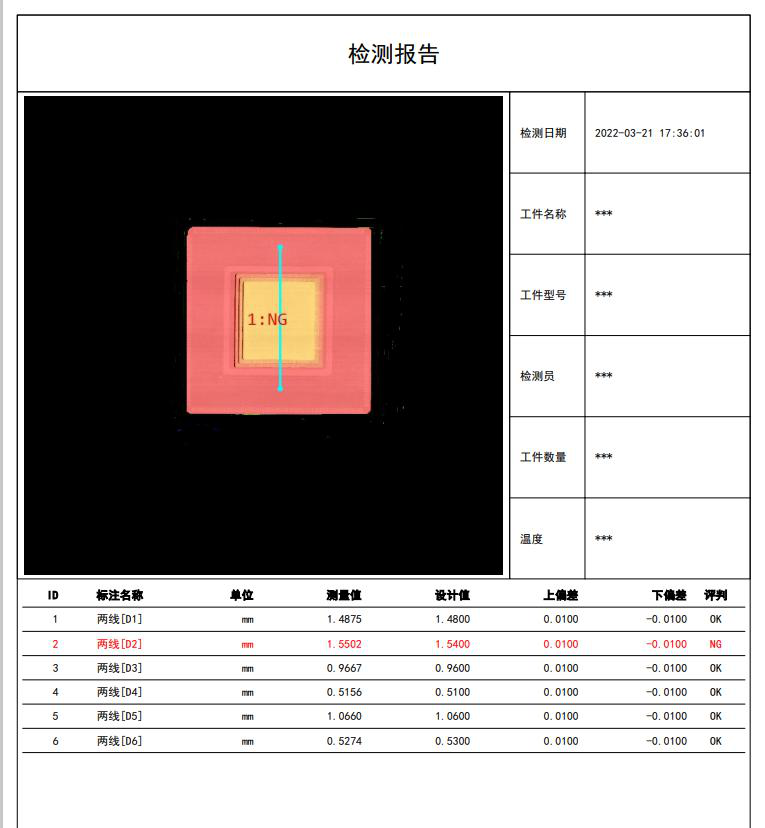

Inspection Report

Inspection Report: “Without ultra-precision measurement, there would be no high-quality, high-end equipment manufacturing.” The CHOTEST VJ series 3D contour measuring instrument, with its fast, convenient, efficient, and stable performance, supports the development of advanced manufacturing industries!