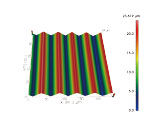

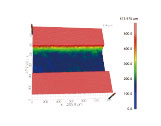

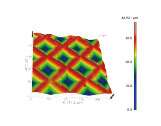

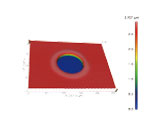

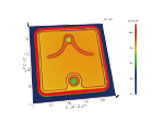

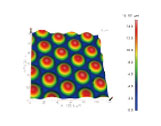

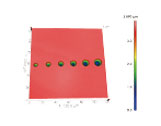

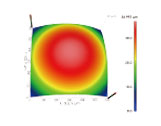

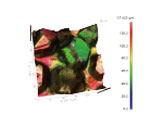

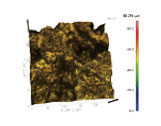

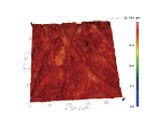

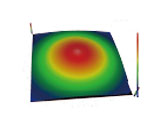

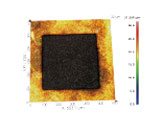

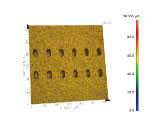

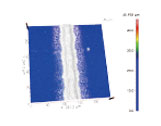

Confocal Microscope VT6300 is dedicated for micro-nano level measurement of various precision components and material surfaces. It can measure the surface of various objects from smooth to rough, low reflectivity to high reflectivity, and the roughness, flatness, micro-geometric profile, curvature, etc.Total more than 300 kinds of 2D and 3D parameters as per four major domestic and foreign standards ISO/ASME/EUR/GBT are provided as evaluation standards

The joystick integrated with the displacement adjustment functions in the three directions of X, Y, and Z can quickly complete the pre-measurement works such as stage translation and 2-way focusing etc.

In addition to the software ZSTOP setting the lower limit of the Z-direction displacement for anti-collision protection, a mechanical and electronic sensor is designed on the Z-axis. When the lens touches the surface of the sample, the instrument automatically enters an emergency stop state to protect the instrument to the greatest extent and reduce the risk of human operation

| Model No. | VT6200 | |

| Size | 1000 ×900×1500mm | |

| Weight | 500kg | |

| Principle | Spinning disk confocal optical system | |

| Objective Lens | 10X,50X(Optional: 5X, 20X,50X,100X APO) | |

| Field of View | 120×120 μm~2.4×2.4 mm | |

|

Step Height Measurement |

Repeatability(1σ) | ≤12nm |

| Accuracy*1 | ≤ ± (0.2+L/100) μm | |

| Display Resolution | 0.1nm | |

|

Width Measurement |

Repeatability(1σ) | 40nm |

| Accuracy*2 | ± 2% | |

| Display Resolution | 1nm | |

|

XY Object Table |

Size | 450x450mm |

| Travel Range | 300x300mm | |

| Load Capacity | 10kg | |

| Control Method | Motorized | |

| Z-Axis | Travel Range | 100mm |

| Control Method | Motorized | |

| Lens Turret | Motorized 5 holes turret | |

| Light Source | White LED | |

|

Operating Environment |

Power Supply | AC100~240V, 50/60Hz, Power 120W |

| Working Temp. | 15℃~30℃, fluctuation < 2℃/60min | |

| Humidity | 5%~95%RH, no condensation | |

| Vibration | VC-C or better | |

| Other | No strong magnetic field, no corrosive gas | |

|

Note: |

||