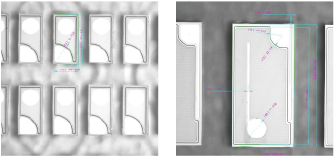

During wafer manufacturing, the offset of the overlay after photoetching process is measured in Photo area, exposure of wafer, and compensation values based on the measurement are imported into the lithography machine to optimize the stability of the wafer photoetching process.

During wafer manufacturing, it requires to control critical dimensions of Die in multiple processes, and SuperView automatically extracts the feature edges of Die, and at the same time it measures all features according to program efficiently and accurately.

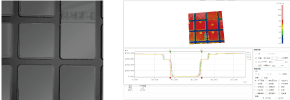

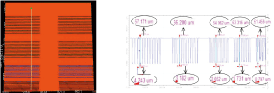

During wafer manufacturing, it is necessary to measure the bottom width of the grooves to check whether the distance between dies is qualified after the previous process in Photo area. The software automatically select multiple parabolas to obtain average value for target positions after auto scanning, then the parameters of the exposure machine is adjusted based on the measurement result in order to meet the process requirements.

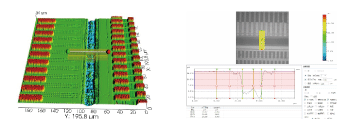

After the laser engraving process, laser U-groove depth and width should be measured. The software can customize the width of the lasso to extract mean value profile curve of the groove, then calculate the average depth & width values of the groove. The parameters of the laser machine is adjusted to meet the process requirements based on measurement results.

| Model No. | BOKI_1000 | ||

| Loading Bin | 4 pcs of Cassette, size is customizable | ||

| Feeding Sensor | With anti-skid function | ||

| Light Source | White/Green LED (single or double is optional) | ||

| Barcode Scanner | Barcode recognition | ||

| Pixel Resolutions | 1024x1024 | ||

| Micro Objective Lens | 10X, 20X, 50X | ||

| Measurement Accurac | 10X:±0.5μm; 20X:±0.4μm; 50X:±0.3μm | ||

| Repeatability(σ)*1 | 10X:±0.2μm; 20X:±0.2μm; 50X:±0.1μm | ||

| Interferometric Objective Lens | 2.5X, 5X, 10X, 20X, 50X, 100X | ||

| Z axis Resolution | 0.1nm | ||

| Lateral Resolution (0.5λ/NA) | 100X~2.5X:0.5μm~3.7μm | ||

| Roughness RMS Repeatability*2 | 0.02nm | ||

| Surface Profile Repeatability | 0.1nm | ||

| Step Height Measurement*3 | Repeatability | Accuracy | |

| 0.1% 1σ | 0.8% | ||

| Software | SuperView | ||

| Field of View | 0.49×0.49mm(@Optical Zoom 0.75×) | ||

| Max Field of View | 6×6mm | ||

| Lens Turret | Manual 3 holes turret(Optional: Motorized 5 holes turret) | ||

|

Object Table |

XY Travel Range | 300×300mm | |

| Load Capacity | 5kg | ||

| Flatness | <10μm | ||

| Control Mode | Motorized | ||

| Z-Axis | Travel Range | 30mm | |

| Control Mode | Motorized | ||

| Vacuum Chuck(Optional) | Negative pressure ≤-80KPa | ||

| Overall Dimension(L×W×H) | 1800×1400×1710mm | ||

| Dustproof Device FFU | Class 1000 | ||

| Required Dust-Free Environment Level | Class 1000 | ||

| Oil-Proof Device |

All guide rails must be provided with oil shields, and oil stains and other substances cannot fall out. |

||

| Equipment Weight | 800KG | ||

| Power Supply | AC220V,50/60HZ,13~14A,3000W | ||

| Compressed Air |

1.Air-floating anti-vibration system: Max flow 1.5LPM; Average flow 1LPM; Pressure 0.6MPa; Hose diameter 6mm; 2.Vacuum chuck: Max flow 250LPM; Average flow 180LPM; Pressure ≤ -80kpa; Hose diameter 8mm; |

||

| Working Environment | Temp.: 15~30°C, humidity : 30~80% (no condensation) | ||

| Safety |

The equipment has door magnetic interlocking function, and the automatic door is equipped with safety grating. |

||

|

*1 Accuracy and repeatablity are obtained by measuring Standard Resolution Test Board. *2 Roughness Performance is obtained by measuring SQ parameters of a Sa 0.2nm silicon wafer in the laboratory environment according to ISO 25178. *3 Step height performance is obtained by measuring a standard 4.7μm stage block in the laboratory environment according to ISO 5436-1: 2000. |

|||