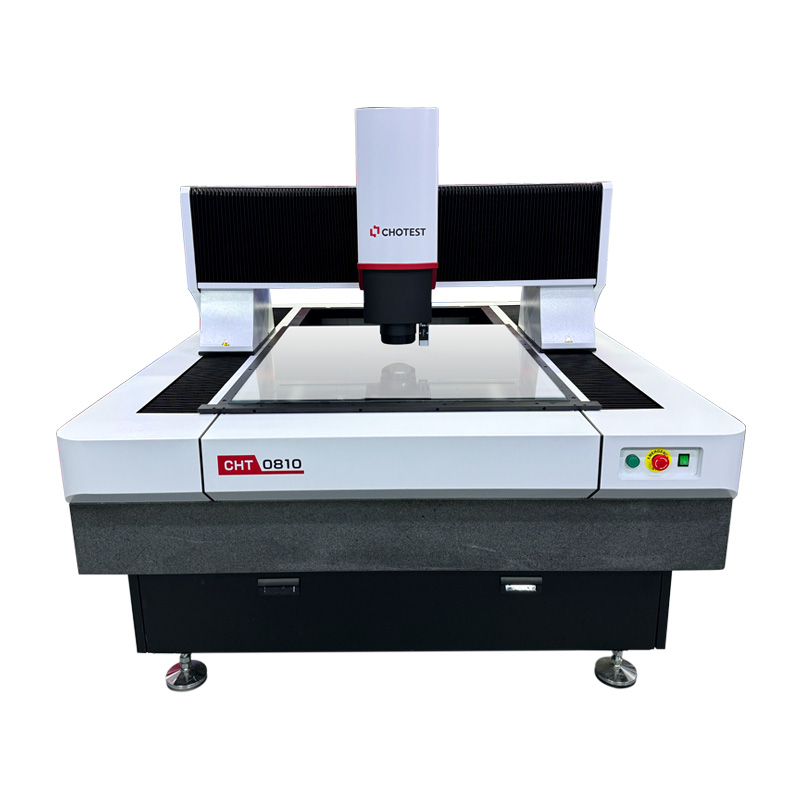

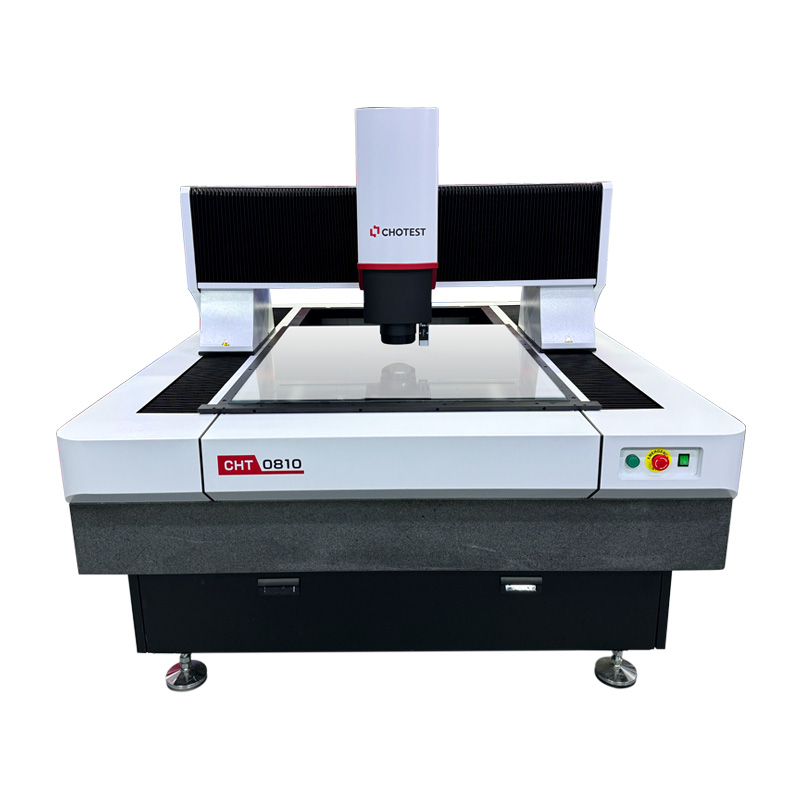

Elevate Precision and Efficiency

Are you seeking to enhance the accuracy and speed of your measurement processes? Chotest's state-of-the-art automated video measuring machine is designed to transform your quality control procedures. Engineered to cater to a wide range of industries, including mechanical, electronic, mold, injection molding, hardware, rubber, low-voltage electrical, magnetic materials, precision stamping, connectors, terminals, mobile phones, home appliances, printed circuit boards, medical devices, clocks, tools, and metrology testing, our machine offers unparalleled precision and efficiency.

Unmatched Measurement Capabilities

Our machine boasts an extensive array of measurement tools and functions, including:

-

Comprehensive Measurement Tools: Scan and extract edge points, multi-segment edge extraction, circular edge point extraction, ellipse extraction, frame selection to extract contour lines, focus points, nearest points, and more.

-

Versatile Geometric Measurements: Accurately measure points, lines, circles (center coordinates, radius, diameter), arcs, centers, angles, distances, line widths, hole positions, hole diameters, number of holes, distance from hole to hole, distance from hole to edge, distance from arc center to hole, distance from arc center to edge, distance from arc high point to arc high point, distance from intersection 1 point to intersection point, and more.

-

Advanced Feature Construction: Create intersection points, center points, extreme points, endpoints, lines connecting two points, parallel lines, perpendicular lines, tangents, bisectors, centerlines, line segment fusion, radius circles, inscribed circles of three lines, inscribed circles of two lines and a radius, and more.

-

Robust Geometric Tolerance Assessment: Evaluate geometric tolerances such as straightness, roundness, profile, position, flatness, symmetry, perpendicularity, concentricity, and parallelism.

-

Flexible Coordinate Systems: Utilize instrument coordinates, point-line, two-point X, two-line, and other workpiece coordinate systems; image registration coordinates; and easily translate, rotate, and manually adjust coordinate systems.

-

Time-Saving Quick Tools: Efficiently measure R angles, horizontal pitch, circular pitch, sieves, slots, contour comparison, springs, O-rings, and other special features.

-

Customizable Settings: Support batch setting of tolerances, proportional level division, and custom color management.

AI-Powered Edge Detection for Unparalleled Accuracy

Our machine incorporates cutting-edge AI-powered edge detection technology, offering significant advantages:

-

User-Friendly AI Model Training: Our intuitive interface and powerful algorithms enable effortless training of AI models.

-

Continuous Optimization: The AI measurement software allows for simultaneous measurement and image storage, enabling continuous optimization and iteration of AI models for enhanced efficiency.

-

Overcoming Measurement Challenges: Effectively addresses traditional measurement pain points such as blurred boundaries, multiple boundaries, excessive burrs, and edge interference.

-

Superior Efficiency and Repeatability: Delivers significantly higher efficiency and better repeatability compared to manual measurement methods.

3D Offline Programming for Streamlined Workflows

Our machine supports 3D offline programming, enabling you to create measurement programs directly from imported 3D data, thereby boosting measurement efficiency. The intuitive interface makes it easy to learn and use.

Comprehensive Data Management and Output

-

Centralized Data Management: All measurement records are centrally managed.

-

CNC Measurement with Barcode Scanning: Supports barcode scanning for CNC measurements.

-

Flexible Querying: Easily search for records based on workpiece model, workpiece name, inspection date, workpiece identification code, and more.

-

Versatile Data Output: Export data to Excel, Word, and TXT formats.

-

CAD Integration: Supports importing and exporting AutoCAD files.

-

Customizable Templates: Supports real-time output to custom Excel templates.

-

SPC Analysis: Generates SPC analysis reports, including statistical values (such as CA, PPK, CPK, PP) and control charts (such as mean and range charts, mean and standard deviation charts, median and range charts, individual and moving range charts).

-

Q-DAS Compatibility: Supports Q-DAS transmission and custom remote data interfacing.

Elevate Your Quality Control with Chotest Experience the future of measurement with Chotest's automated video measuring machine. Contact us today to learn more about how our solutions can benefit your business.