2024-09-03

Large gantry machine tool is an important processing equipment for aircraft, ships, nuclear power, heavy equipment. As we all know: the machining accuracy of the machine tool depends directly on the geometric accuracy of its machine guide. In the geometric accuracy testing, straightness, perpendicularity and horizontality of the traditional testing methods can not be a one-stop solution, more time-consuming and laborious, and the data can not be unified management.

Traditional inspection methods

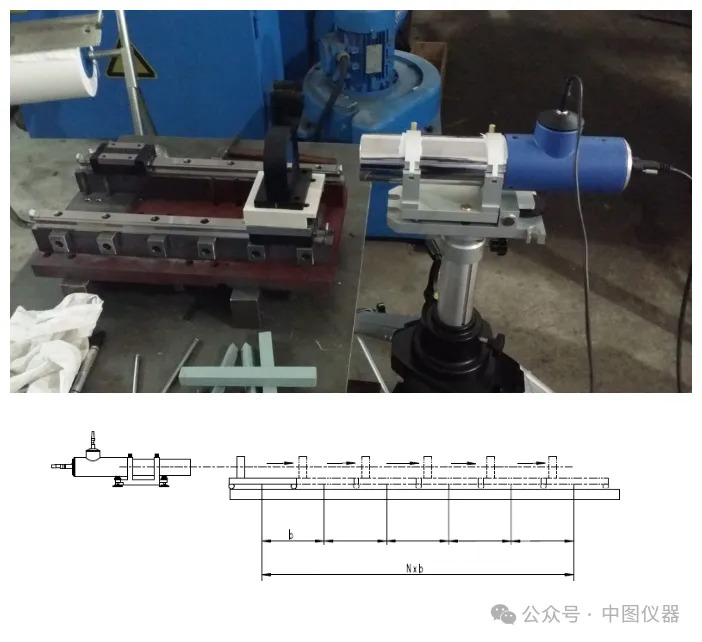

The straightness of the machine tool guideway inspection method is usually used to pull the table method, self-collimator detection method or level meter detection method.

▲Pull table method to measure the straightness of the guideway

▲ Self-collimator to measure the straightness of the guideway

The perpendicularity detection method of the machine tool guideway adopts the marble right-angle ruler detection method.

▲ Marble Right Angle Ruler Measuring Guideway Perpendicularity

The levelness of the machine bed is checked by using the level meter test method.

▲ Leveling the machine bed with a spirit level

As the size of large gantry machine tools is getting bigger and bigger, such as twenty to thirty meters of large gantry milling machine. The traditional measurement methods for straightness, perpendicularity and flatness are facing dilemmas such as limited range, handling difficulties, human errors and data management.

As an advanced spatial large size measurement tool, laser tracking instrument has the advantages of large measuring range (measuring radius up to 80 meters), high precision (15um+6um/m), high degree of digitization, and it has become an important means in the process of large-scale gantry machine tool mounting and adjusting.

1. Straightness detection and setup

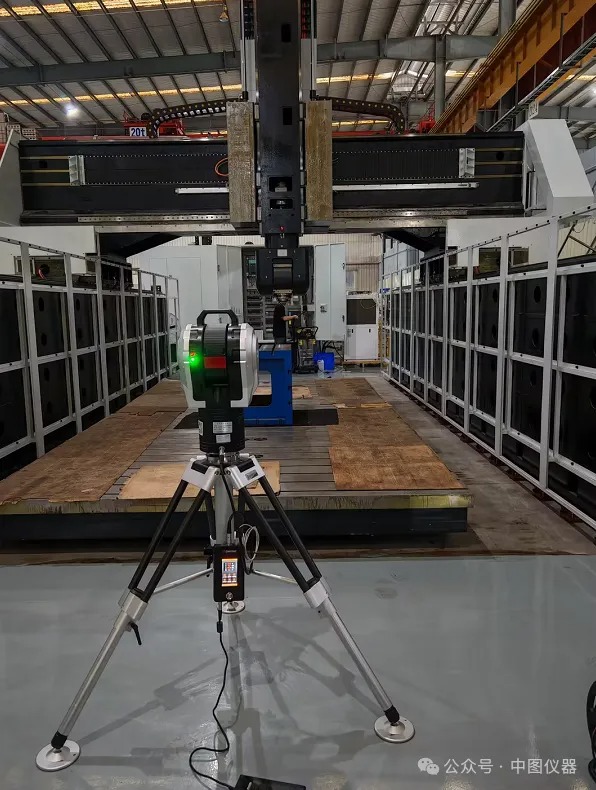

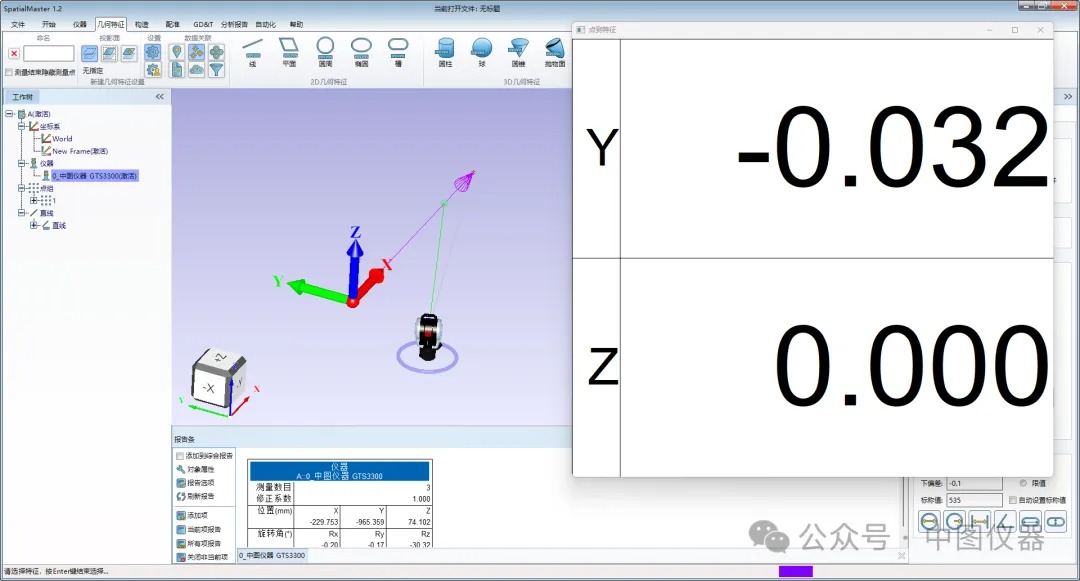

The GTS laser tracker is set up in front of the machine (as shown below), and the target ball is fixed on the guideway slide or machine spindle.

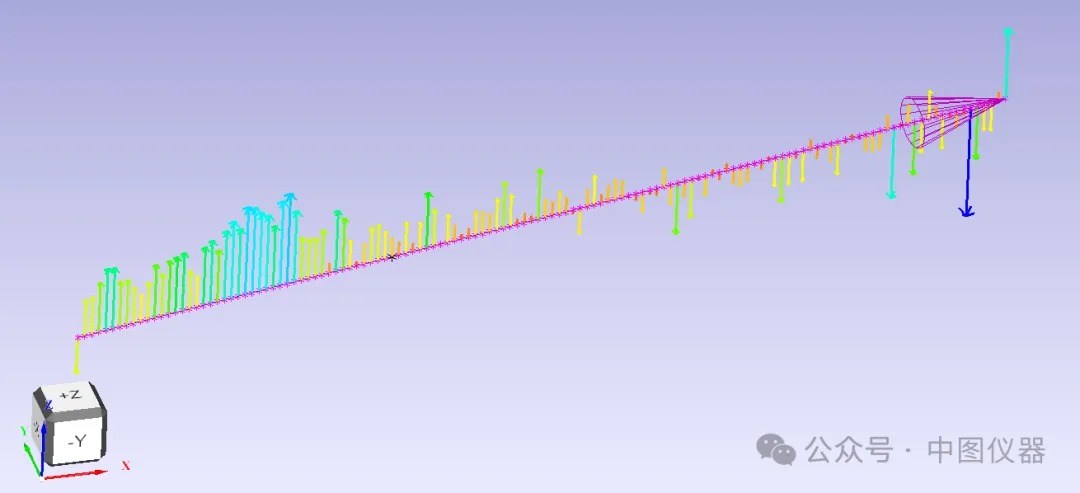

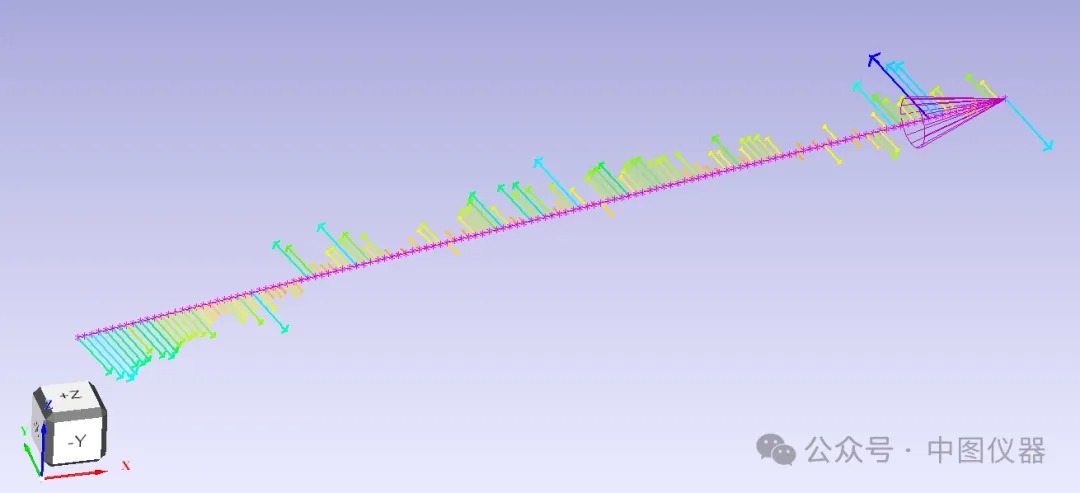

Starting from the starting position of the guideway, data acquisition is carried out according to the set distance. Do the fitting straight line processing in the measurement software, that is, get the straightness error in both directions.

Vertical straightness

Horizontal straightness

Straightness Adjustment: Simply add a monitoring window to the fitted straight line on the software and move the slider to digitally adjust the guideway, which can be used to adjust the straightness in both directions at the same time.

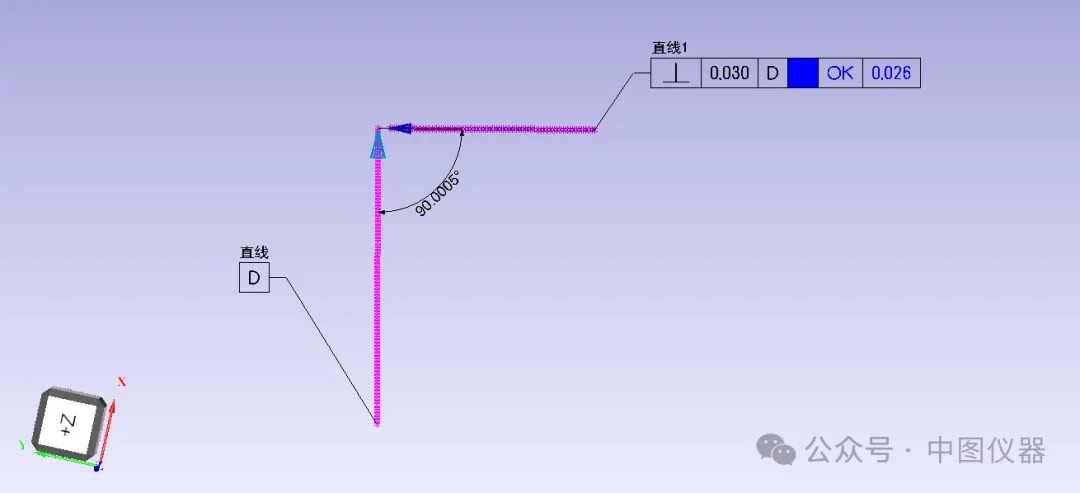

2. Perpendicularity detection and setup

GTS laser tracker is set up in front of the machine tool, and the target ball is fixed on the main axis of the machine tool. First move along the reference axis for measurement, and then move along the other axis for measurement, you can measure the perpendicularity of the two axes.

Perpendicularity adjustment: establish a coordinate system with the reference axis as the main axis and the other axis as the secondary axis, move the reference axis to any position to collect a point, add a monitoring window, move the other axis, and then adjust the perpendicularity of the two axes.

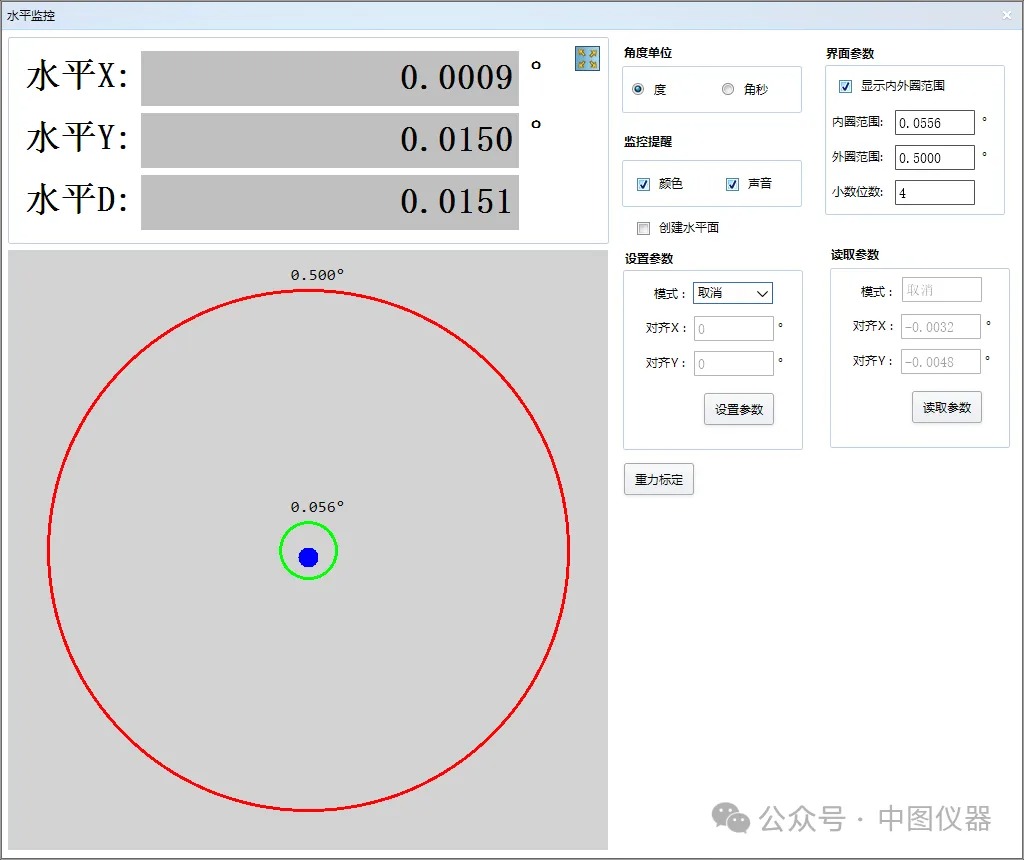

3.Level detection and adjustment

The GTS laser tracker has a built-in electronic level with an accuracy of up to 1 arc second, and the level of the machine can be checked and adjusted directly using the tracker.

The laser tracker performs gravity alignment, the software can generate the horizontal plane, and then measure the machine tool working platform, you can compare the absolute difference between the machine tool working platform and the horizontal plane, add a monitoring window to the horizontal plane, and the target ball is placed on the working platform, you can adjust the level of the working platform.

In addition to the above, the laser tracker can also replace the laser interferometer for linear positioning accuracy and angular positioning accuracy measurement, as well as speed, acceleration and other dynamic measurement analysis.

GTS laser tracker, as an advanced measuring tool, has significant advantages in enhancing the accuracy and efficiency of large gantry machine tool setup. Through the introduction of laser tracker, manufacturing enterprises can effectively improve the setup accuracy, shorten the setup time, enhance the overall production efficiency, and bring more competitive advantages for manufacturing enterprises.