2022-08-05

The laser interferometer takes the light wave as the carrier and uses the laser as the length reference. Laser interferometers are not only widely used in high-end equipment such as CNC machine tools, laser cutting machines, lithography machines, etc., but also in the field of metrology verification.

1. Universal Length Measuring Machine Calibration

The indication error of the traditional Universal length measuring machine (ULM) is mainly calibrated with gauge blocks, which are greatly affected by environmental factors and require high calibration conditions. The ULM with a range greater than 1m needs to be calibrated in sections, which is inefficient. When using the laser interferometer for calibration. , not only can improve the efficiency, but also can compensate the air temperature, pressure, humidity and material temperature through the environmental compensation unit to improve the calibration accuracy.

2. CMM indicator error measurement

With the update and development of CMM technology, it is difficult to use traditional gauge blocks, ball plates, etc. to meet the detection requirements of large CMMs. Laser interferometer has high measurement accuracy, large measurement range, and rich measurement database. It is suitable for Measure the geometric errors of the three coordinates.

3. Displacement sensor calibration

Verifying displacement sensors with laser interferometers has become a development trend that offers high measurement accuracy, fast response times, and easy digital measurement.

A precision guide rail was designed in the measurement, and the mirror and the measured sensor were put together for synchronous detection, so as to form a comparison. The automatic verification system of displacement sensor and laser interferometer were used to test and compare the fixed-length displacement, and the reciprocating test results were obtained.

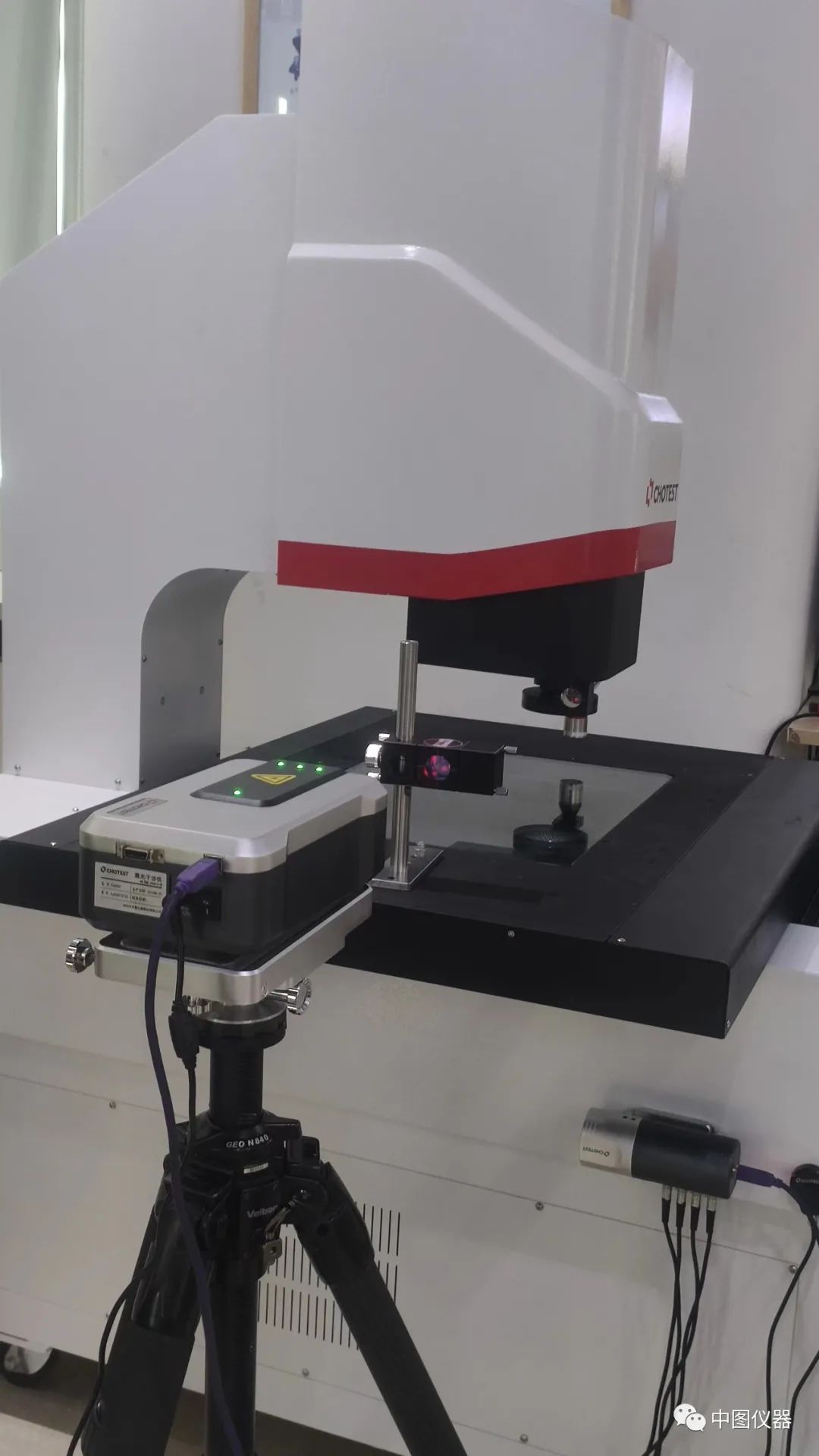

4. Video measuring machine positioning accuracy measurement

There are a variety of problems associated with the traditional VMM detection method. For instance, the comparison method of line rulers has low detection accuracy, large measurement errors, an inability to analyze the cause of the improvement, and inefficiency in detection.

Using the laser interferometer can quickly detect the positioning error of the VMM, perform arithmetic analysis on the measurement data, and use the software to produce compensation files to quickly implement two-dimensional plane multi-point compensation. In this way, the difficulty of precision detection in the equipment manufacturing process can be greatly reduced, and the detection efficiency and compensation efficiency can be improved.