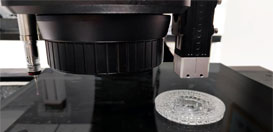

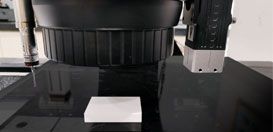

Automatic video measuring machines CHT series covers different measurement ranges offers powerful functionality and can perform precise measurements of surface dimensions, contours, angles, positions, and geometric tolerances for various complex parts.

Automatic video measuring machines CHT series can be used in machinery, electronics, mold, injection molding, hardware, rubber, low-voltage electrical appliances, magnetic materials, precision stamping, connection Plug-ins, connectors, terminals, mobile phones, home appliances, printed circuit boards, medical equipment, clocks, knives, measurement and testing, etc.

Automatically output SPC analysis report and support remote data docking

Extractdion Tools

Extractdion Tools

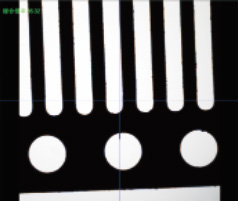

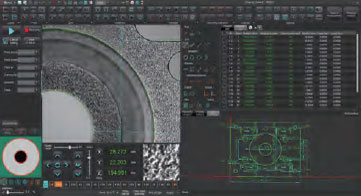

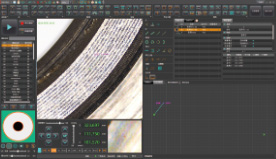

Scanning to extract edge points, multi-segment edge point extraction,circular edge point extraction, ellipse extraction, frame selection to extract contour lines, focus points, closest points, etc.

Annotation Tools

Annotation Tools

Point, line, circle (center coordinates, radius, diameter), arc, center, angle, distance, line width, hole position, aperture, number of holes, distance from hole to hole, distance from hole to edge, distance from arc center to hole, the distance from the center of the arc to the side, the distance from the high point of the arc to the high point of the arc, and the distance from the intersection to the intersection, etc.

Construction

Construction

Intersection point, center point, extreme point, end point, line connecting two points, parallel line, perpendicular line, tangent line, bisector,Centerlines, line segment fusion, radius circle, three-line inscribed circle, two-line radius inscribed circle, etc.

GD&T

GD&T

Straightness,roundness,profile,position,parallelism,symmetry, perpendicularity, concentricity and other form and position tolerance evaluation

Coordinate

Coordinate

Instrument coordinate system, point to line, point to point, line to line and other workpiece coordinate systems; image registration coordinate system;Can translate, rotate, manually adjust the coordinate system

Special tools

Special tools

R angle,horizontal pitch,circumferential pitch,screen,slot,contour comparison,spring,O-ring and other special tools for rapid measurement .

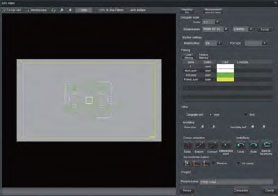

Support tolerance batch setting, scale classification, and color custom management

Support segmental programming control of surface light, transmitted light and coaxial light , automatically identify the measurement position, and obtain uniform and stable measurement results every time.

| Model No. | CHT682 | ||

| Travel Range | X(mm) | 600 | |

| Y(mm) | 800 | ||

| Z(mm) | 200 | ||

| Structure Type | Bridge | ||

| Base Material | Granite | ||

| Monitor | 24" LCD(1920×1080) | ||

| Image Sensor | 1.6MP High definition colorful industrial camera | ||

| Resolution of Glass scale | 0.1μm | ||

| Lens | 8.3X motroized lens | ||

| Magnification | Optical Zoom: 0.6X~5.0X, Image Zoom: 27~229X | ||

| Light | Back light | Telecentric transmission illumination | |

| Ring Light | 6 rings and 8 segments (256 levels) surface light | ||

| Coaxial Light | LED | ||

| Accuracy*1 | X/Y | (2.5+L/200)μm | |

| X⊥Y | (3.0+L/200)μm | ||

| Z*2 | (4.5+L/200)μm | ||

| Max Speed | XY | 500mm/s | |

| Z | 100mm/s | ||

| Height Meas. (Optical Probe) (Optional) |

Measuring Range(X*Y) | 500*800mm | |

| Max Depth/Diameter(H/Φ) | 1.64 |

||

| Dia. of Beam | Φ100μm(Φ18μm optional) | ||

| Resolution | 0.25μm | ||

| Z Non-movetment |

Range(Z) | ±2mm | |

| Accuracy | ±2μm | ||

| Z Movetment |

Range(Z) | 200mm | |

| Accuracy | ±(6+0.01H)μm, H is Z movement height in mm | ||

| Size | 1200×2000×1700mm | ||

| Weight | 2000kg | ||

| Loading Capacity | 25kg | ||

| Power | 2500W | ||

| Sensor Option | (1)Touch probe; (2)Optical probe | ||

| Motion Control | Servo control system | ||

| Software | VisionX | ||

| Input | AC200-240V, 50/60Hz | ||

| Working Environment | Temp.20℃ ±2℃ , Humidity 20~80%, Vibration<0.002g, Less than 15Hz | ||

| Note: *1 In the focus position, the environment temperature is +20 °C ± 1.0 °C, and the load on the table is 5 kg or less; L is the moving range of the table in mm. *2 It is mechanical accuracy, and actual accuracy depends on object surface where lens focuses. |

|||