2022-04-15

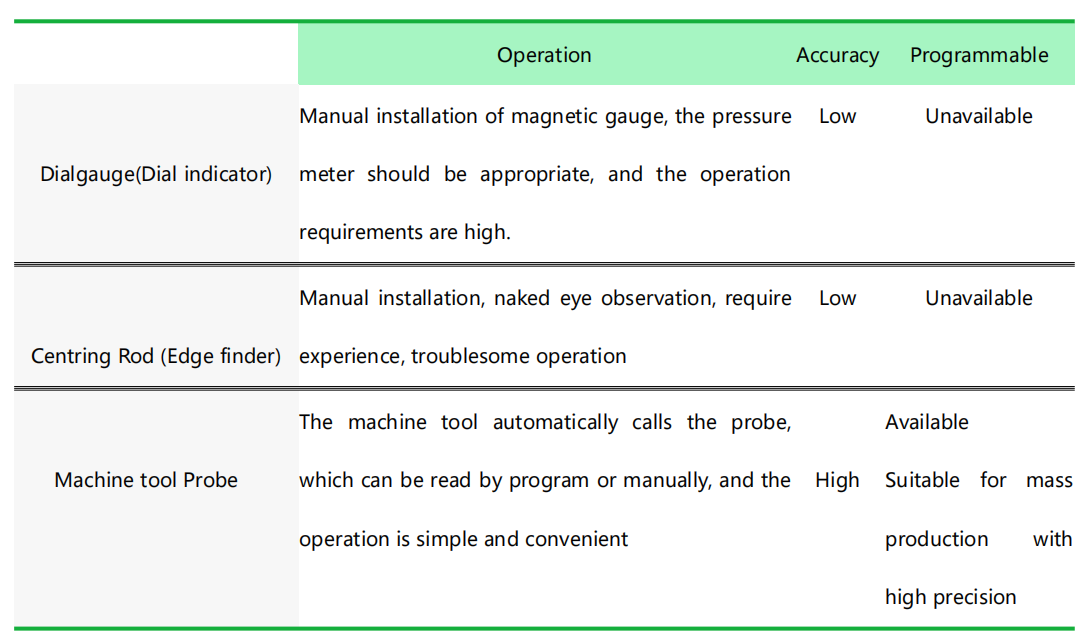

The centering is to find the zero point of the workpiece to be processed. If the centering is not standardized, it will lead to errors in processing and even the workpiece will be scrapped. Therefore, mastering the centering skills is an essential skill for every CNC operator. At present, the commonly used centring tools include dialgauge (dial indicator), centring rod (edge finder) and machine tool probe.

Find the centre by dialgauge(dial indicator) would need manual operation, which has high requirements for personnel. Due to the long operation time, and possible human error, this method has been gradually phased out, mainly used by some self-employed or processing plants with low accuracy requirements.

The centring rod (edge finder) must be rotated when centring, and it needs to be judged by the human eye whether it touches the workpiece. The resolution of the human eye varies from person to person, and it is easy to cause the visual fatigue.

Therefore, the accuracy is very limited, this method is suitable for the workpiece which has few requirements on precision. Also it can not measure the hole which diameter is less than 10mm.

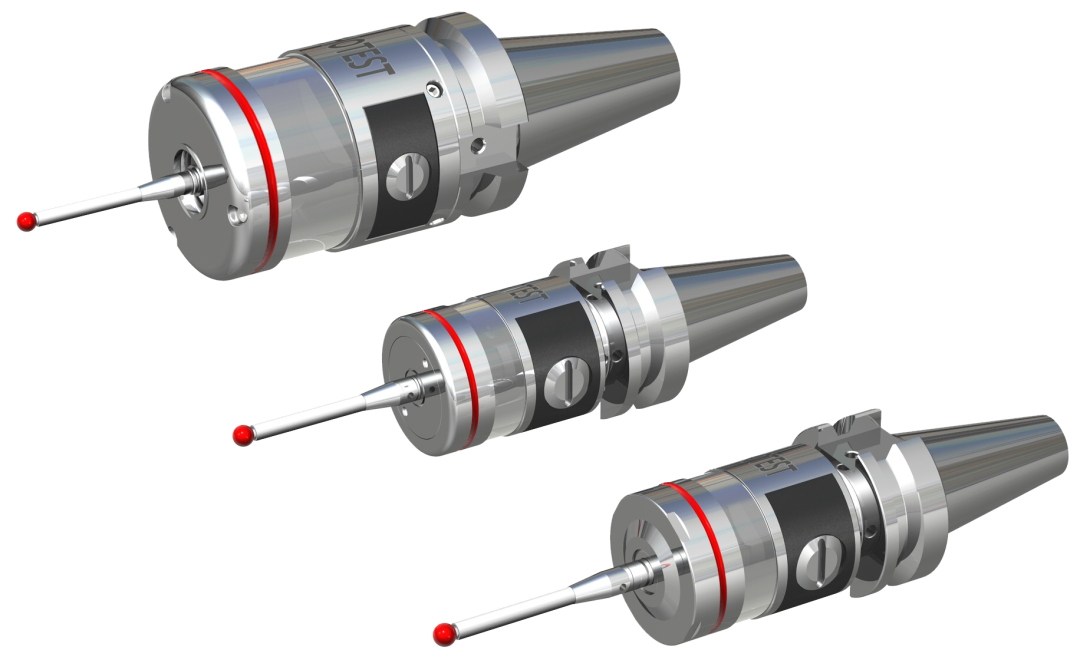

After the machine tool probe is installed, use the probe to touch each side of the workpiece in turn (manual or program control), and record the machine tool coordinates of the current point, calculate the center of the workpiece, and ensure the centering accuracy, thereby improving the machining accuracy.

In the use of machine tool probes, it completely gets rid of the limitations of the operator's technical level. It transforms the operation that originally required experience and handfeel in the correction and processing process into a scientific, simple, and everyone-can-master process. Therefore, the use of machine tools Probes are becoming the mainstream of CNC machining at present.

The machine tool probe has a repeatability of up to 1um, can measure holes with a diameter of more than 2mm. The stylus can be replaced, the stylus ball and length can be selected according to user requirements to fit different applications.