1. High precision of measurement: Resolution is up to nanoscale based on the technology of laser interferometry; With high-precision environmental compensation unit, influences to measuring result from ambient temperature, pressure, humidity and material temperature are eliminated; It can ensure long-term frequency stability of laser by using the laser thermal frequency stabilization control system; The design of separating interferoscope from host avoids heat distortion of interferoscope, which ensures the stability of interference optical path.

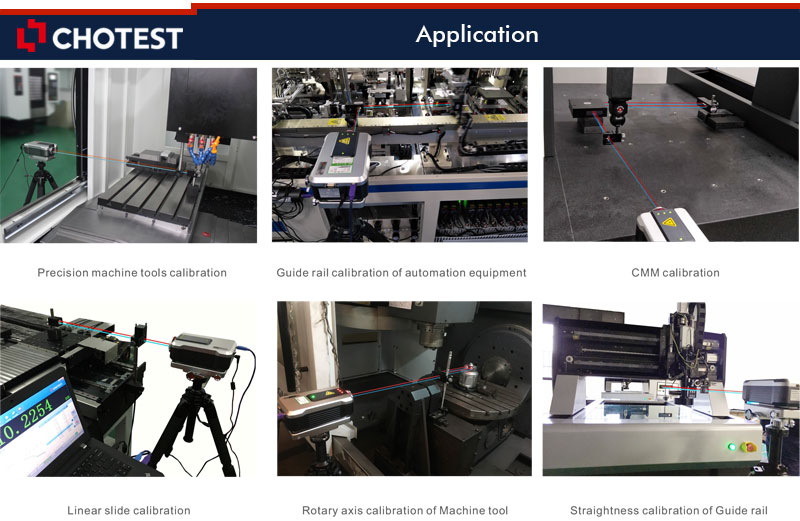

2. It can measure linearity, angle, straightness, perpendicularity and other geometrical parameters; It can measure the linear positioning accuracy and repeated positioning accuracy of guide rails for CNC machine tools, coordinate measuring machines and other precision motion equipments; It can measure the pitch angle, swing angle, perpendicularity and straightness of the guide rails, in addition it can calibrate rotary axis of machine tools.

3. According to compensation settings by user, the system automatically generates error compensation table for calibration of machine tools.

4. With functions of Dynamic measurements (displacement-time curve, velocity-time curve, acceleration-time curve), amplitude measurement and frequency analysis, it can analyze vibration test of machine tool, dynamic characteristics of ball screw, response characteristics of drive system, dynamic characteristics of guide rail and so on.

5. Built-in domestic & international standards, such as GB, ISO, BS, ANSI, DIN, JIS and so on. The system analyzes and processes data according to relevant standard, finally generates test reports including corresponding carve charts and data.

6. Can automatically acquire the parameters of environment temperature, material temperature, environment humidity and atmospheric pressure. Can set environmental compensation by hand, or by system automatically.

7. With centralized database management for measuring records, the user can query and manage the measuring records according to object type, testing institution, manufacturing number, inspector, submitted institution, equipment number, inspection date and effective date; Can export the data to Word, Excel, AutoCAD (optional) files.

8. Easy to install: Basic weight 15kg, convenient and portable.

| System parameters: | ||||

| 1. Measuring method: single frequency | ||||

| 2. Laser frequency accuracy: 0.05ppm | ||||

| 3. Dynamic capture rate: 50kHz | ||||

| 4. Warm-up time: about 6 min | ||||

| 5. Operating temperature: (0-40)℃ | ||||

| 6. Environment temperature: (0-40)℃, humidity: 0-95% | ||||

| 7. Storage temperature: -20℃-70℃ | ||||

| Environmental sensors: | ||||

| 1. Atmospheric temperature sensor : ±0.1℃ (0-40)℃, resolution: 0.01℃ | ||||

| 2. Material temperature sensor: ±0.1℃ (0-55)℃, resolution: 0.01℃ | ||||

| 3. Atmospheric humidity sensor: ±6%RH (0-95%) | ||||

| 4. Atmospheric pressure sensor: ±0.1kPa (65~115)kPa | ||||

| Linear measurement: | ||||

| 1. Measuring range: (0-80)m | ||||

| 2. Measuring accuracy: 0.5ppm (0-40)℃ | ||||

| 3. Measuring resolution: 1nm | ||||

| 4. Maximum measuring speed: 4m/s | ||||

| Angle measurement: | ||||

| 1. Axial range: (0-15)m | ||||

| 2. Measuring range: ±10° | ||||

| 3. Accuracy: ±(0.02%R+0.1+0.24M)″ (R is indicating value, unit: ″; M is measured length in m) | ||||

| 4. Measuring resolution: 0.01″ | ||||

| Flatness measurement: | ||||

| 1. Axial range: (0-15) m | ||||

| 2. Flatness measuring range: ±1.5 mm | ||||

| 3. Accuracy: ±(0.2%R+0.02M2) μm (R is indicating value in μm; M is measured length in meters) | ||||

| 4. Substrate size: 180mm adjustable, 360mm adjustable | ||||

| 5. Measuring resolution: 0.1μm | ||||

| Straightness measurement: | ||||

| Item | Axis range | Measuring range | Accuracy | Resolution |

| Short straightness | (0.1-4)m | ±3.0mm | ±(0.5+0.25%R+0.15M2)μm | 0.01μm |

| Long straightness | (1-20)m | ±3.0mm | ±(5.0+2.5%R+0.015M2)μm | 0.1μm |

| Note: R is indicating value in μm; M is measured length in meters | ||||

| Squareness measurement: | ||||

| Item | Axis range | Measuring range | Accuracy | Resolution |

| Short straightness | (0.1-3)m | ±3/M mm/m | ±(2.5+0.25%R+0.8M)μm/m | 0.01μm/m |

| Long straightness | (1-15)m | ±3M mm/m | ±(2.5+2.5%R+0.08M)μm/m | 0.01μm/m |

| Note: R is indicating value in μm; M is measured length in meters | ||||

| Rotary axis measurement: | ||||

| 1. Measuring range of angle: 0-360° | ||||

| 2. Max axis rotation speed: No limit( <5"), 10rpm(>5") | ||||

| 3. Pitch accuracy of precision turntable: ±1″ | ||||

| 4. Resolution: 0.1″ | ||||

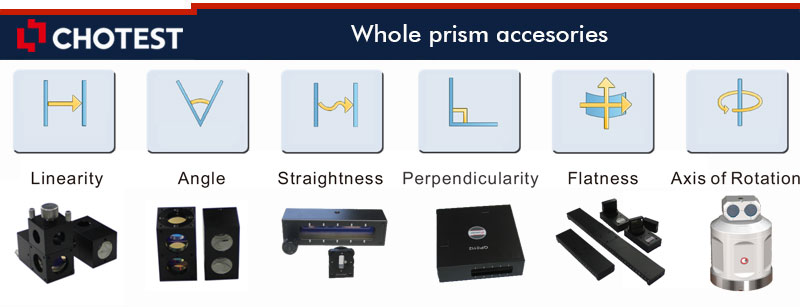

Laser interferometer is recognized as a high precision, high sensitive measuring method by applying light wavelength as criterion, and is widely used in high-end manufacturing domain. SJ6000 laser interferometer insists of high-frequency Helium-Neon laser generator from a USA supplier, high-precision environmental compensation modules, high-precision laser interference signal processing system, high-performance computer control system. By applying with thermal frequency stabilization technology of laser dual-longitudinal mode and geometric parameters interference optical path design, SJ6000 can output long-term stable and high-precision(0.05ppm) laser quickly(about 6 minutes) which has powerful anti-interference performance. With different prism modules, it can measure linearity, angle, straightness, Flatness and perpendicularity, in addition it can analyze dynamic characteristics. SJ6000 has many advantages, such as high precision, high speed, high resolution, long range.

1. SJ6000 host machine 1 pc

2. Environmental compensation modules 1 set

3. Prism modules

For linear measurement (standard) 1 set

For micro angle measurement(optional) 1 set

For straightness measurement (optional) 1 set

For perpendicularity measurement (optional ) 1 set

For flatness measurement (optional) 1 set

For axis of rotation measurement (optional) 1 set

4. Measuring Software 1 pc

5. Laptop computer 1 pc

6. Portable case 1 pc

7. Universal tripod 1 pc

8. Pan/tilt holder 1 pc

9. Magnetic bases for prism module 1 set

10. Instruction Manual 1 pc

11. Product certification and Warranty card 1 set