Lens

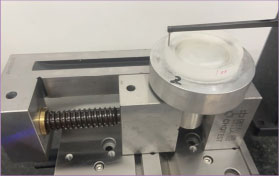

Lens Intraocular lens mold

Intraocular lens mold Vehicle Lens

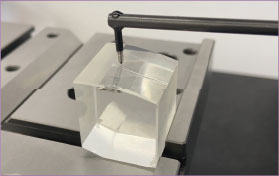

Vehicle Lens Infrared lens

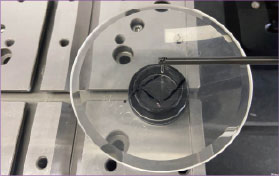

Infrared lens Optical mold

Optical mold Lens

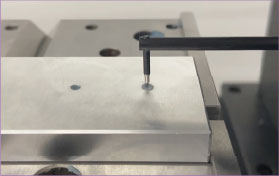

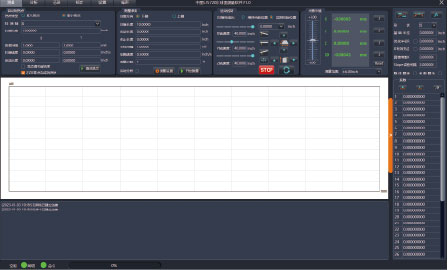

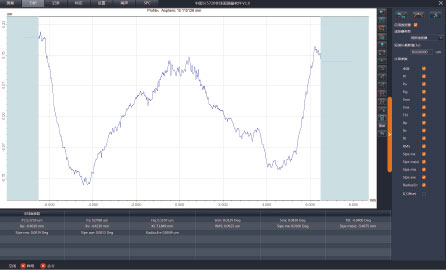

LensThe SJ5720-OPT series is a capable to measure both surface roughness and profile after once scanning. Moreover, there is a dedicated software module for measurement and analysis of large aspheric surface, so this series is an ideal measurement solution for the optical lens industry.

It can also be used for profile and roughness measurement for large curved surface, such as bearings, artificial joints, precision molds, gears, blades, etc. Consequently, it is widely used in precision machining, automobiles, bearings, machine tools, molds, precision hardware and other industries.

Professional aspheric surface measurement software can analyze all aspheric surface parameters.

There are some self-checking parameters in the software, so the correctness of the input formula can be determined by self-checking.

| Model No. | SJ5720-OPT200 | ||

|

Profile Measurement |

Measuring Range | X | 0~200mm |

| Z | 0~500mm | ||

| Z1 | ±6mm(Optional: ±12mm) | ||

| Resolution | 0.001um | ||

| Accuracy | Z1 *1 | ≤±(0.5+0.03 H)μm(H,mm) | |

| Pt *2 | Pt≤0.2μm | ||

| Standard Ball *3 | ≤±(1+R/20)μm(R,mm) | ||

| Angle *4 | ≤±1′ | ||

|

Moving Speed |

X | 0~20mm/s | |

| Z | 0~20mm/s | ||

| Scanning Speed | 0.05~5mm/s | ||

| X Straightness *5 | ≤0.25μm/200mm | ||

| Measuring Force | 0.5mN,0.75mN,1mN,2mN,3mN(Adjustable) | ||

|

Roughness Measurement |

Ra Masurement Range | Ra0.012μm~Ra12.5μm | |

| Accuracy *6 |

Ra0.012μm ~ Ra3 . 2 μm: ≤±(3nm+2.0%A),A(Ra)μm Ra3.201μm ~ Ra12.5μm : ≤±(3nm+3.5%A),A(Ra)μm |

||

| Repeatability (1δ) *7 | 1δ≤1nm | ||

| Measurement Residual *8 | Rq≤3nm | ||

| Roughness Parameters |

R roughness: Rp, Rv, Rz, Rc, Rt, Ra, Rq, Rsk, Rku, RSm, RPc, Rdq, Rdc, Rmr, Rmax, Rpm, tp, Htp, Pc, Rda, Ry, Sm, S, Rpq, Rvq, Rmq, RzJ, Rv1max, Rp1max, Rz1max, Rmr(Rz/4), maxRa, R5z, R3z, Rh, Dq, Lq, SD Key roughness: Rcore: Rk, Rpk, Rvk, Mr1, Mr2, A1, A2 Profile: Pa, Pq, Pt, Pz, Pp, Pv, PSm, Psk, Pku, Pdq, Pdc, Pc, PPc, Pvq, Pmr, Pmq, Rad, PzJ, Pmax, StpHt, TIR, Avg, Slope, Area+, Area-, Area, Profl, Edge, StpWd, Bumpht Waviness of profile: Wa, Wq, Wt, Wz, Wp, Wv, WSm, Wsk, Wku, Wdq, Wdc, Wmr, Wpc, Wc, Wh, Wmr(WZ/4) Motif: R, AR, W, AW, Rx, Wx, Wte, Nr, Ncrx, Nw, Cpm, CR, CF, CL ISO5436: Pt5436, D |

||

| Aspheric Masurement Parameters |

Micro profile parameters: Pt, Pa, Fig; Inclination parameters: Smx , Smn ; Horizontal axis angle parameter: Tilt; Distance parameters between the optical axis and the contour: Xp , Xv , Xt ; Root mean square roughness parameter: RMS; Slope parameters: Slpe mx , Slpemx (x), Slperms; Vertex radius error parameter: Radius Err |

||

| Filter | Gaussian filter, 2RC filter, zero phase filter | ||

| Sampling Length | 0.008, 0.08, 0.25, 0.8, 2.5, 8.0 or 25mm Selectable | ||

| Evaluation Length | Auto calculation | ||

| Size(L×W×H) | 800×500×1080(mm) | ||

| Weight | 265kg | ||

|

*1 The accuracy is based on the measurement standard gauge block. *2 The accuracy is based on the Pt test of standard ball smaller than diameter 25mm. *3 The accuracy is based on the verifcation of the ф 50mm standard ball with the arc exceeds 90 degrees. *4 The accuracy is based on the measurement of the angle of polygonal prism. *5 The accuracy is based on the measurement of optical flat. *6 The accuracy is based on the measurement of standard roughness block. *7 The repeatability is based on the measurement of 0,1-0.2μm square wave roughness block and standard step height block. *8 The accuracy is is based on the measurement of 1 nm level roughness block and optical flat. |

|||