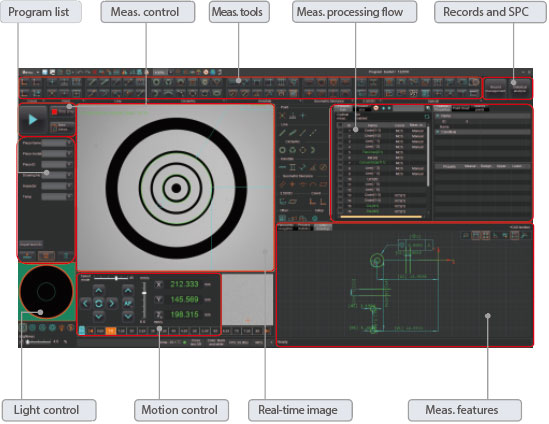

1. Measurement tools: Extracting edge points by scanning, extracting edge points by multi-segment, extracting edge points by circle, ellipse extraction, extracting contour line by frame selection, focus point, nearest points, etc.

2. Measure geometric features: Point, line, circle (center coordinate, radius, diameter), arc, center, angle, distance, line width, hole site, aperture, number of holes, distance from hole to hole, hole to edge, distance from the arc center to the hole, distance from the arc center to the edge, distance from the arc high point to the other arc high point, distance from the intersection to the intersection, etc.

3. Construction features: Intersection, center point, extreme point, endpoint, two-point connection, parallel line, perpendicular line, tangent, bisector, center line, line segment fusion, drawing circle by radius, drawing inscribed circle among three lines, drawing inscribed circle by two lines & radius , etc.

4. Geometric tolerance: Straightness, roundness, contour, position, parallelism, symmetry, perpendicularity, concentricity, and other shape and position tolerance evaluation.

Replaceable RGB surface light

Integrate 3D topography measurement

Output SPC analysis report, which includes statistical values (such as CA, PPK, CPK, PP, etc.) and control charts (such as mean and range charts, mean and standard deviation charts, median and range charts, single value and moving range chart).

Can output Excel, Word, PDF, TXT reports and AutoCAD files.

Support exporting data to designated excel file according to designated template in real time

Support Q-DAS transmission according to designated format.

Support data exchanging via HTTP or socket protocol

| Model No. | Novator562 | ||||

| Travel Range | X(mm) | 500 | |||

| Y(mm) | 600 | ||||

| Z(mm) | 200 | ||||

| Structure Type | Bridge | ||||

| Base Material | Granite | ||||

| Monitor | 24" LCD(1920×1080) | ||||

| Image Sensor | 5MP High definition colorful industrial camera | ||||

| Resolution of Glass scale | 0.1μm | ||||

| Lens | 13.3X motorized lens | ||||

| Magnification | Optical Zoom: 0.6X~8.0X, Image Zoom: 17X~380X | ||||

| F.O.V. | Max: 13x11mm; Min:1.0x0.8mm | ||||

| Light | Back light | Telecentric transmission illumination | |||

| Ring Light | 6 rings and 8 segments (256 levels) surface light(or RGB surface light,Optional) | ||||

| Coaxial Light | LED | ||||

| Accuracy*1 | X/Y | (1.8+L/250)μm | |||

| X⊥Y | (2.2+L/250)μm | ||||

| Z | (3.0+L/200)μm | ||||

| Z measuring range*3 | 5mm | ||||

| 3D Scanning*2 | Scanning width*4 | 30mm | |||

| Repeatability*5 | ±1μm | ||||

| Z Accuracy*5 | ±0.1%F.S. | ||||

| Scanning speed | 10~80mm/s | ||||

| Fly-Shooting Mode | Support | ||||

| Navigation camera | Support | ||||

| Sensor Option | (1)Touch probe; (2)Optical probe | ||||

| Max Speed | XY | 500mm/s | |||

| Z | 100mm/s | ||||

| Size | 1100×1820×1700mm | ||||

| Weight | 1650kg | ||||

| Loading Capacity | 50kg | ||||

| Power | 2500W | ||||

| Motion Control | Servo control system | ||||

| Software | VisionX | ||||

| Input | AC200~240V, 50/60Hz | ||||

| Working Environment | Temp.20℃ ±2℃ , Humidity 20~80%, Vibration<0.002g, Less than15Hz | ||||

|

*1 In the focus position, the environment temperature is +20 °C ± 1.0 °C, and the load on the table is 5 kg or less; L is the moving range of the table (mm) *2 Optional line-scanning probe is required. *3 Measuring range 5mm~40mm optional. *4 Scanning width 30mm~145mm optional. *5 Environment temperature is +20 °C ± 1.0 °C |

|||||