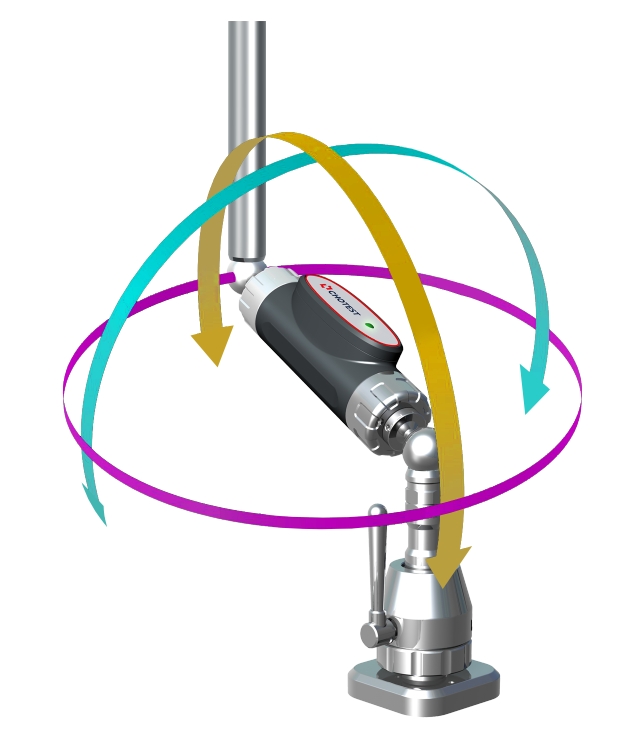

1. Simple, fast The measurement software with guided operation can generate the machine running program automatically. With simple setting the round track test on three orthogonal planes can be completed in 10~15 minutes.

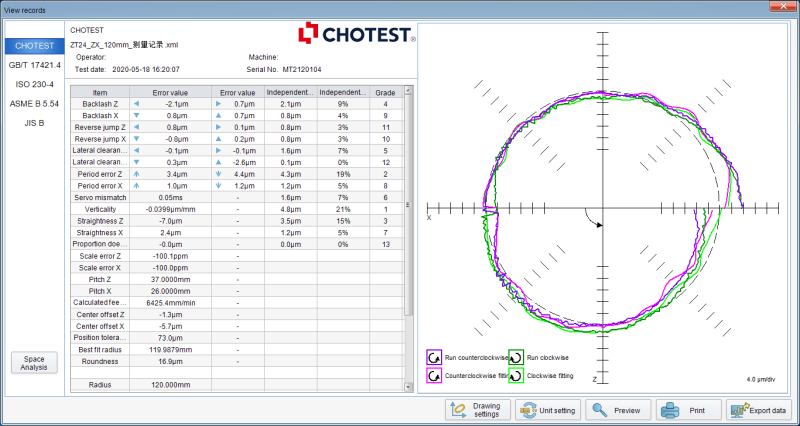

2. Powerful analysis function Comprehensive diagnosis report provides a full and professional assessment of machine performance. Taking 360 degree measurement at the XY plane as an example, it can analyze: backlash X, backlash Y, reverse jump X, reverse jump Y, lateral gap X, lateral gap Y, period error X, period error Y, servo Mismatch, perpendicularity, straightness X, straightness Y, proportional mismatch, scale error X, scale error Y, thread pitch X, thread pitch Y, feed rate, center offset X, center offset Y, position tolerance, the best fitting radius, roundness.

3. Wireless operation Data is transferred to the laptop computer via wireless Bluetooth.

| Parameters | |

| Communication | Bluetooth(Typical 10m) |

| Power supply | Li-battery |

| Resolution | 0.1μm |

| Measuring accuracy | ±(0.7+0.3%L)μm |

| Measuring range | ±1.0mm |

| Sensor range | ±2.0mm |

| Sample rate | 1000Hz |

| Working Temperature | (0~40)℃ |

| Size | 150mm×26mm×21mm |

Designed to inspect machine tools quickly and improve machining quality, MT21 Wireless Ballbar provides a fast & cost- effective solution for machine tools inspection at low cost.

MT21 software with guided operation implements the round track test on three orthogonal planes quickly and simply. Analysis report with the graphic format according to GB17421-4, ISO230-4, ASMEB5.54, or JISB standards can be generated automatically, and the overall measurement values (roundness, roundness deviation) of the positional accuracy are calculated. MT21 achieves the real spatial diagnosis for machine tools.

1. MT21 Wireless Ballbar

2. Master gauge

3. Offset setting ball

4. Centric holder

5. Tool cup

6. Extension bar 50mm, 100mm, 150mm

7. Software

8. Portable suitcase

9. User Manualbr

10. Product certificate and warranty card