1. Measure gauge blocks, thread gauges, plain gauges, Taper thread/plain gauges, pin gauge, caliper, spline gauges, setting bars, snap gauges, internal/external micrometers, feeler gauges, Dial indicators, dial bore gauge, dial test gauges, internal micrometer three points, etc.

| Item No. | SJ5100-300A/B | SJ5100-600A/B | SJ5100-1000A/B | |

|

Absolute measurement |

Outside range | (0~340)mm | (0~640)mm | (0~1040)mm |

| Inside range | (0.7~200)mm | (0.7~500)mm | (0.7~900)mm | |

| Indication error | A series: ±(0.12+L/1000)μm; B series: ±(0.20+L/1000)μm | |||

| (Note: L is measured length in mm) | ||||

| Repeatability (2s) | A series: 0.08μm; B series: 0.10μm | |||

| Resolution | 0.01μm | |||

| Measuring force | 0.05N, 0.1N, 0.3N, 0.5N, (1~10N) continuously adjustable by hand | |||

| Max pitch diameter(mm) | 200(Ring gauge) / 250(Plug gauge) | |||

| Dimension(mm) | 1400×400×450 | 1400×400×450 | 1700×400×450 | |

| Weight(kg) | 150 | 150 | 180 | |

|

Five-axis object table |

Item No. | ST-30.1 | ||

| Z-axis | (0-50)mm | |||

| Y-axis | ±25mm | |||

| X-axis floation | ±10mm | |||

| Z-axis rotation | ±3° | |||

| Y-axis swing | ±3° | |||

| Loading capacity | <=50Kg | |||

| Dimension | 350mm×125mm | |||

Thanks to precision glass-scale, precision guide rail and precision temperature compensation unit, cooperating with different probes and workholders, SJ5100 achieves high-precision measurement of various dimensional gauges. Moreover, because straightness of precision guide rail is every small, its repeatability is excellent by applying by bidirectional constant measuring force technology. After the software records the coordinates from precision glass-scale and introduces the feedback data of measuring force device and temperature sensor, the dimensional parameters are calculated according to the relevant definitions and formulas from selected norm. The whole measurement process can be completed in 3minutes.

Standard configuration

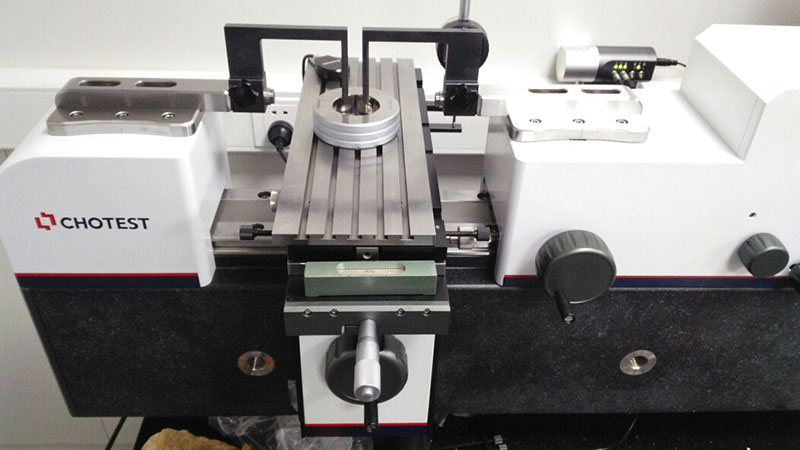

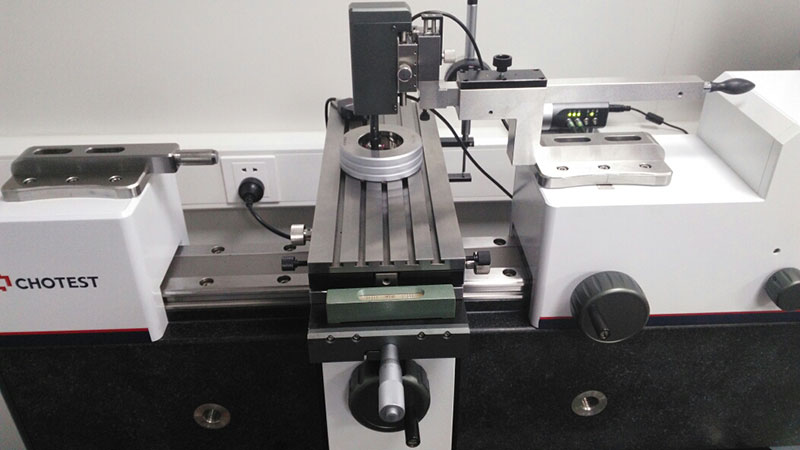

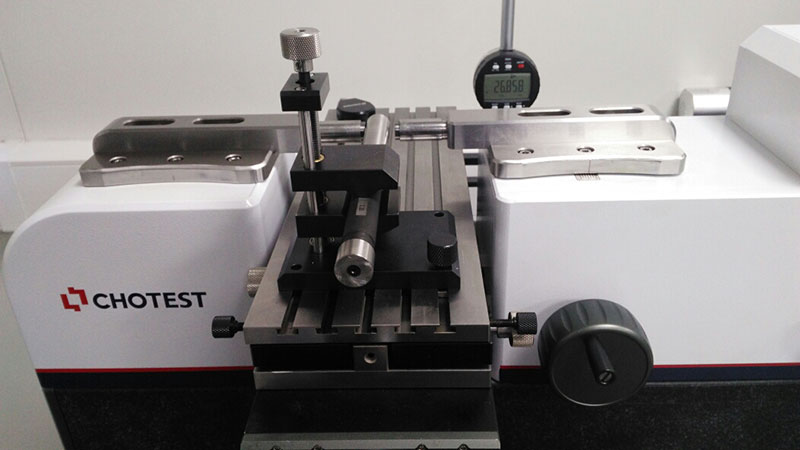

1. SJ5100 host machine

2. ST-30.1 five-axis object table

3. ST-S1.1 one-coordinate floating object table

4. Measuring probes

5. Three-wire for thread measurement

6. SF-P60.1 workholder for plug gauges

7. SF-V1.1 V-shaped supporting block for setting bar

8. SF-GB1.1 and SF-GB2.1 supporting fixture for gauge block

9. ST-CL1.1 and ST-CL2.1 clamping fixture

10. SDE-R200.1 Precision inside dimension measuring device

11. SB-T12.1 T-shaped ruby ball probe

12. SB-S4.1 single ruby ball probe

13. SH-L1.1 big measuring jaw for ring gauge

14. SH-L2.1 small measuring jaw for ring gauge

15. Standard plain ring gauge Φ40mm

16. Measuring software

17. Built-in popular standards in database

18. Desktop computer

20. Supporting fixture DLB-200 for monitor

21. Aluminum alloy suitcase for accessories

22. Temperature compensation device

23. Product certification and Warranty card

24. User manual

25. Free services and repairs

Optional configuration

1. Marble work table

2. SDE-Z200.1 Precision inside dimension measuring device (for internal measurement and taper thread gauge measurement)

3. SF-Z1.1 workholder for taper plain/thread ring/plug gauge

4. Digital micrometer indicator with cable(for Taper thread/plain gauge)

5. Measuring jaw (for spline ring gauge/ outer ring of bearing)

6. Measuring cap (for spline plug gauge/ inner ring of bearing)

7. Small measuring bar for spline gauge measurement(12 pairs):

8. Small measuring bar for bearing measurement(2 pairs)

9. T-shaped ruby ball probe(For M3, M4 thread ring gauges)

10. Single ruby ball probe(For ring gauges Φ0.7~4mm)

11. SR-H65.1: Axis raising(H=65mm ) block for measuring bar RH-6.5_8.0: Small measuring bar with plain face Φ8

12. Portal bubble level gauge (for five-axis object adjustment)

13. Workholder for snap gauge measurement

14. Measuring jaw for outside micrometer

15. Workholder and its accessories for micrometer measurement

16. Paralleled probe for outside micrometer measurement

17. Workholder and probe for dial test indicators

18. Foot pedal board for sampling

19. Electronic moistureproof cabinet