2. Measure the above objects with digital display automatically.

3. Measure the above objects with imperial system automatically.

4. Semi-auto testing function, which is for testing dial indicators with stains.

5. Automatic zeroing after click Start.

6. Overstandard hinting in measuring process.

7. Process and qualify the measured data automatically.

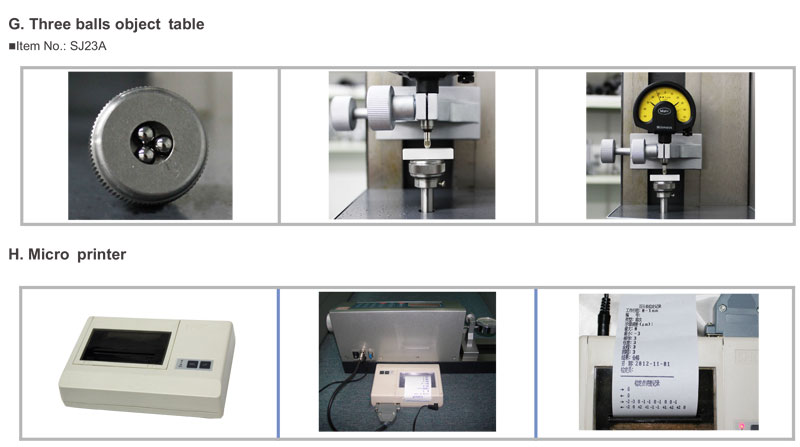

8. Can display and print former test data and test reports including error sheet or curve of measuring points and deviation values compared to specified standard.

9. Can query and manage the test records according to object type, manufacturer, manufacturing number, inspector, submitted institution, equipment number, inspection date or effective date etc.

10. Can print multiple selected test records at once.

11. Can export test data in Word or Excel.

12. Data backup and restore.

13.Support user-defined template of report.

14. Support user-defined program and tolerance.

| Model No. | SJ2100 |

| Measuring Range | (0-100)mm |

| Resolution | 0.1µm |

| Repeatability | 0.1µm |

| Reading Accuracy |

1/60 of division value for Resolution 0.01mm dial indicator 1/30 of division value for Resolution 0.001mm dial indicator |

| Indication error |

Random 1mm ≤1.0µm Random 2mm ≤1.0µm Random 10mm ≤1.5µm Random 30mm ≤2.0µm Random 50mm ≤2.5µm 100mm ≤4.0µm |

| Hysteresis | ≤0.5µm |

| Interface | RS232 (Can convert to USB) |

| Input Voltage | AC100~240V 50Hz |

| Operation Environment | Temp.(20±2)℃, RH(50~70)% |

| Dimension | 700*205*165 mm |

| Weight | 30kg |

1. Artificial intelligence: Do not need manual reading & recording & calculating and manual adjustment with hand wheel or microdrum.

(1) Scale and indication value are identified automatically by the CCD camera which completely simulates manual reading, without observed, read and recorded by operator

(2) Function of automatic zeroing without manual zeroing before testing;

(3) A motor controlled by computer drives measuring spindle to arrive measuring point accurately, without manual adjustment by hand wheel or microdrum

(4) Powerful software automatically processes and qualifies the measured data, finally generates test result, additionally all test records can be queried, displayed, saved, printed.

2. Special light source:

(1) Patented no-reflective light source(Patent No.: ZL200620056214.1)

(2) If the surface of dial indicator is convex, the no-reflective light source is necessary to assure reliability of test data.

3. New patented slider: National utility model patent(Patent No.: ZL201220239454.0) Eliminate gap in forward – reverse measuring by reducing the wear between the slider and the guide rail; High repeatability: significantly improve lifespan of the slider and guide rail.

4. Humanized design: Thanks to user-friendly interface, operation of software is extremely simple. With Humanized design for both machine and software, the operator can be trained to use it in a short time. Particularly the system can identify pointer of dial indicator and acquire the indication value of object accurately even if the dial indicator is not in the right center of camera, so the dial indicator can be installed fast, and that simplifies the operating procedure and save operating time.

5. Large-capacity database With built-in large-capacity storage space for database, the system can record and save all test records automatically.

6. Powerful print Support user-defined template of report(curve, sheet or error value). Test data can be saved automatically, particularly a number of test reports can be printed at once.

Standard configuration

1. SJ2100 host machine

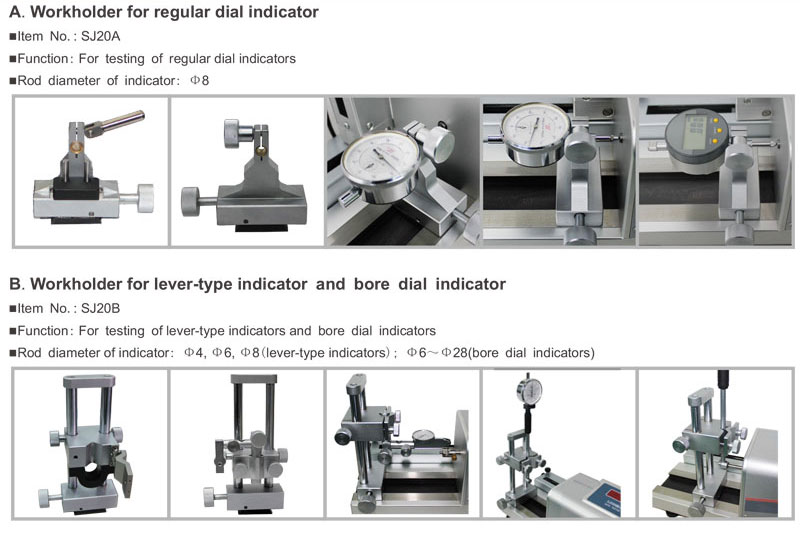

2. Workholder

3. Desktop computer

4. SJ22 Extension bar for camera

5. Aluminum alloy case

6. Measuring software

7. Cables

8. User manual

9. Product certification and Warranty card

Optional configuration

1. J30A digital forcemeter

2. SJ21A Fixture for radial force to dial indicator Function: test influence of radial force to dial indicator

3. SJ20C Workholder for expanding head bore dial indicator and steel ball-type dial indicator Function: For testing of expanding head bore dial indicators and Steel ball-type dial indicators

4. SJ20G workholder for imperial system indicator with stem diameter Ф9.525mm

5. SJ20J workholder for torsion spring indicator and Mechanical comparator with stem diameter Ф28mm '\

6. SJ20H Quick workholder for dial indicator with stem diameter Ф10

7. SJ20I Quick workholder for dial indicator with stem diameter Ф20

8. Customize special workholder for stem diameter except Ф4-28mm

9. Summer or winter laboratory uniform