1. Surface contour evaluation: It can evaluate radius, angle, distance, coordinates, circle, circular cross section, and determine the points, each intersectant point, coordinate axis, straight line, vertical line, circle and circular cross section, and analyze the straightness, roundness of contour; More functions: (1)Establish a regression line and a circle (2)Establish the points, intersectant points, free points, center point, the highest point and the lowest point (3)Establish the coordinate system (4)Calculate the radius, distance, angle, coordinates and linear deviation (5)Compare actual value with nominal value (6)The measurement program runs automatically 2. SJ5701 can evaluate surface roughness: Ra, Rz, Rt, RS, RSm, Rp, Rv, Rq, Rt, Rmax, D, Rmr curve, Rdc, etc. 3. CNC Automatic mode is supported; SPC statistics and analysis are supported 4. Support to import CAD file and annotate CAD profile. 5. Support to import PDF profile data. 6. Can export test data to the Word, Excel, AutoCAD(Optional) 7. Output multiple kinds of report format, and support user-defined report, or customize report(optional) 8. Can query and manage the test records according to object type, manufacturer, manufacturing number, inspector, submitted institution, equipment number, inspection date or effective date etc. 9. Can print multiple selected test records or test certificates from database at once time 10. User-friendly software interface 11. Data backup and restore

| Item No | SJ5760-PR | ||

| Profile measurement: | |||

| (1) X-axis | |||

| Measuring range | (0~200)mm | ||

| Indication error |

±(0.6+1.5L/100)µm, L is horizontal measured length in mm |

||

| Resolution | 0.01μm | ||

| Strightness | 2μm/200mm | ||

| Scanning speed | (0.05~5)mm/s | ||

| Moving speed | (0~10)mm/s | ||

| (2) Z1-axis | |||

| Measuring range | ±25mm | ||

| Indication error |

±(0.6+|4H|/100)µm H is vertical measured height in mm |

||

| Resolution | 0.01μm | ||

| (3) Z-axis | |||

| Measuring range | (0~450)mm | ||

| Moving speed | (0~10)mm/s | ||

| (4) Measuring force | (10~150)mN | ||

| (5) Max gradient | uphill 77 º / downhill 83º | ||

| (6) Object table | Rotation angle: 360º; X, Y movement: 15mm | ||

| (7) Dimension & weight |

Marble base: 800×450×100mm Overall:(850×450×1000)mm 150kg |

||

| (8) Operating environment |

No strong magnetic field, no vibration, no corrosive gas; Operating temperature: 20 ± 2℃; Relative humidity: 10-70% |

||

| Roughness measurement: | |||

| (1) Basic parameters | |||

| Measuring range | X: 200mm; Z0:±800µm | ||

| Error of strightness | ≤0.15µm/20mm, ≤0.4µm/100mm | ||

| Indication error | ± ( 0.005+0.025A) μm, A ( Ra) μm | ||

| Resolution | Z0: 0.001µm | ||

| Scanning speed | 0.05~0.5 mm/s adjustable | ||

Built-in roughtness standards

| Parameter classification | Parameters |

| Roughness | Ra , Rq , Rz , Rmax , Rpc , Rz-JIS , Rt , Rp , Rv , R3z , RSm , Rs , Rsk , |

| Rku , Rdq , Rlq , Rdc , RHSC , Rmr , Rz-L , Rp-L , R3z-L , Rdc-L , RMr-L , | |

| Pdc-L , PMr-L | |

| Key roughness | Rk , Rpk , Rvk , Rpkx , Rvkx , Mr1 , Mr2 , A1 , A2 , Vo |

| Profile | Pa , Pq , Pt , Pp , Pv , PSm , Psk , Pku , Pdq , Plq , Pdc , PHSC , PPc , PMr |

| Waviness of Profile | Wa , Wq , Wt , Wp , Wv , WSm , Wsk , Wku , Wdg , Wdc , WMr |

| Motif | R , Ar , W , Aw , Rx , Wx , Wte , Nr , Ncrx , Nw , Cpm , CR , CF , CL |

| ISO 5436 | Pt , D |

1. High precision, high stability, high repeatability: fully meet the measurement requirements of test object. 1)The world's leading high-precision linear encoder system and high-precision inductance measurement system; 2)High-precision grinding rail is made of good material with high wear resistance. 3)High-performance linear motor driving system 2. Intelligent measurement software Thanks to friendly software interface, the operator can grasp the basic operation of the machine. 3. Can measure multiple parameters Automated evaluation of roughness including Ra, Rz, Rp, Rt, etc. 4. Measuring force Measuring force controlled by voice coil motor driving system is continuously adjustable from 10mN to 150mN, and the resolution of measuring force is 0.2mN; 5. Intelligent protection system Once the measuring probe collides with test object / workholder, or tensile force to measuring probe is too large during scanning process, the machine will stop scanning in order to protect measuring probe and measuring system. 6. Flexible manual control The machine is equipped with a joystick, which can be used to position the probe before measurement. The operator can control the measuring probe to move up and down, left and right quickly without the computer.

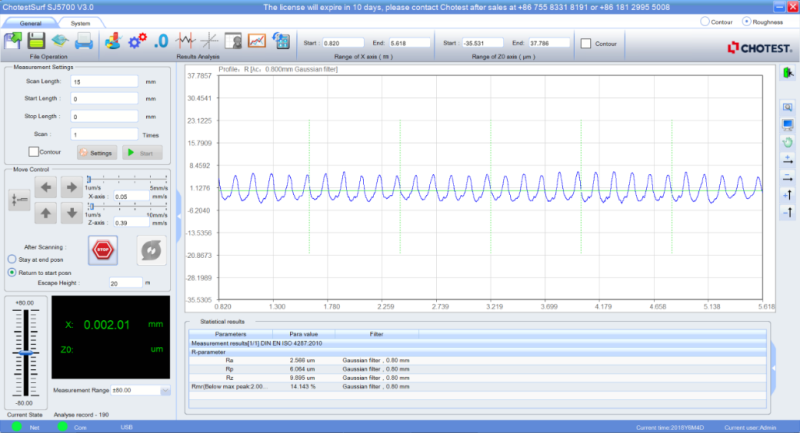

Scanning curve of Roughness

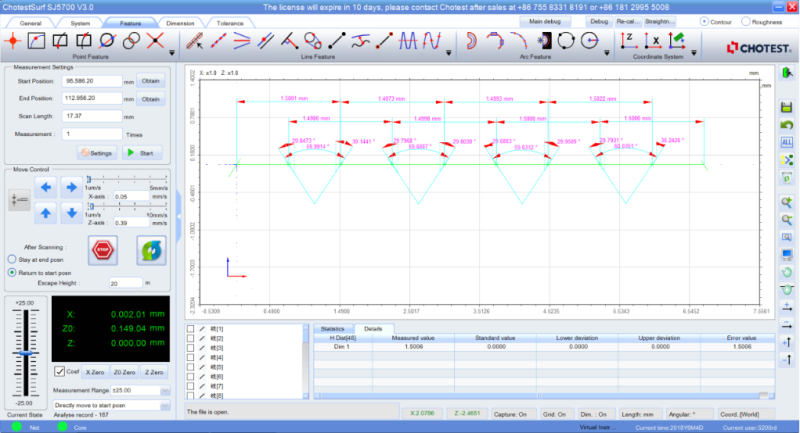

Scanning curve of Profile

Standard configuration:

1. Host machine 1)Profile measurement module 2)Long-arm roughness module(including Measuring probe) 2.Combined calibration gauge for profile 3.Roughness master gauge Ra: 0.8 4. Combined probe-- DQ-30 5. Jaw vice 6. Object table 7. Portable joystick 8. Measuring software 9. Aluminium alloy suitcase for accessories 10. User manual 11. Product certification and Warranty card